手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@fyplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

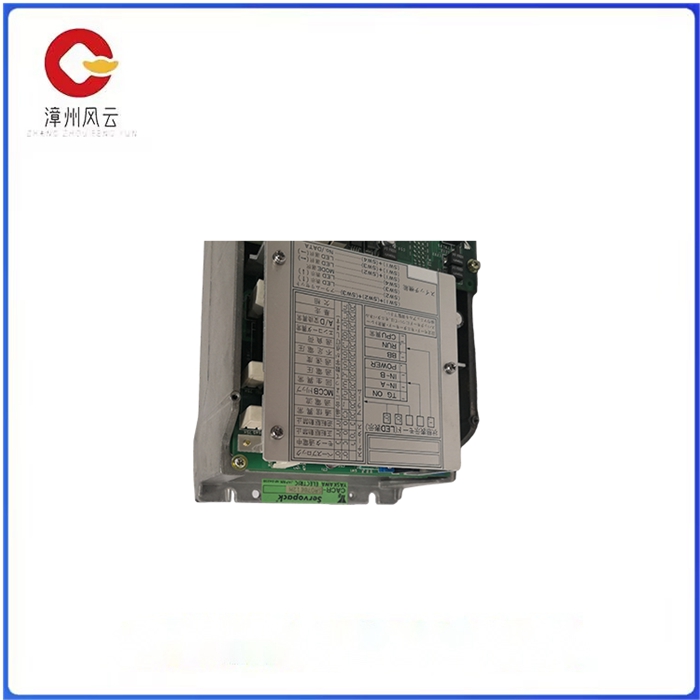

CACR-SR07BE12M控制伺服驱动模块品牌YASKAWA产品特性原装保障是否进口否产地欧美加工定制否工作电压标准VV输出频率标准kHz产品认证原厂系列DC

产品详情

YASKAWA CACR-SR07BE12M 控制脉冲模块是用于控制和驱动伺服电机系统的关键组件之一。以下是这个模块的主要产品功能:

伺服电机控制:CACR-SR07BE12M 控制脉冲模块的主要功能是控制和驱动伺服电机。它能够生成脉冲信号,以精确控制电机的位置、速度和加速度。

高性能运动控制:模块通常支持高性能运动控制,能够实现快速的运动和高精度的定位,适用于需要高性能运动的应用。

多轴控制:它通常具有多轴控制能力,允许用户同时控制多个伺服电机,协调它们的运动以实现复杂的运动任务。

位置反馈:模块通常接收来自编码器或其他位置传感器的反馈信号,以实时监测电机的位置,并对其进行闭环控制。

速度控制:CACR-SR07BE12M 控制脉冲模块可以用于控制电机的速度,确保电机以所需的速度运行。

加速度控制:它通常支持加速度控制,使电机能够在瞬时改变速度时平稳加速或减速。

通信接口:模块通常具有通信接口,例如以太网、串口等,以便与其他控制设备或上级控制系统进行数据交换和通信。

实时监测和反馈:模块通常能够提供实时监测数据,以及对电机状态和性能的实时反馈。

The YASKAWA CACR-SR07BE12M control pulse module is one of the key components used to control and drive servo motor systems. The following are the main product features of this module:

Servo motor control: The main function of CACR-SR07BE12M control pulse module is to control and drive the servo motor. It is capable of generating pulse signals to precisely control the position, speed and acceleration of the motor.

High-performance motion control: Modules typically support high-performance motion control, enabling fast motion and high-precision positioning, suitable for applications requiring high-performance motion.

Multi-axis control: It usually has multi-axis control capabilities, allowing users to control multiple servo motors at the same time, coordinating their movements to achieve complex motion tasks.

Position feedback: The module usually receives feedback signals from encoders or other position sensors to monitor the position of the motor in real time and to control it in a closed loop.

Speed control: The CACR-SR07BE12M control pulse module can be used to control the speed of the motor to ensure that the motor is running at the desired speed.

Acceleration control: It usually supports acceleration control, which enables the motor to accelerate or decelerate smoothly when changing speed instantaneously.

Communication interface: The module usually has a communication interface, such as Ethernet, serial port, etc., in order to exchange data and communicate with other control devices or superior control systems.

Real-time monitoring and feedback: Modules are often able to provide real-time monitoring data, as well as real-time feedback on motor status and performance.

相关推荐