手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

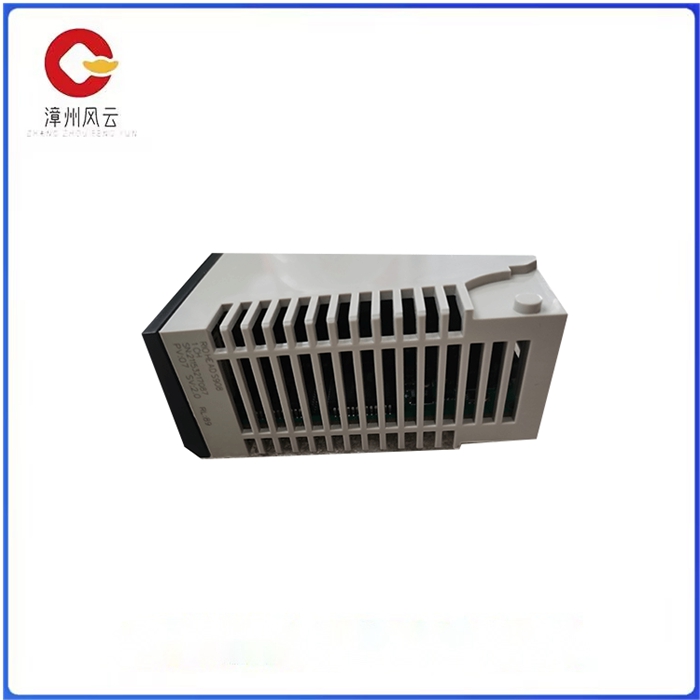

140HLI34000中断输入模块工业自动化系统规格140HLI34000工作电压10V~30VDC分辨率:温度0.1℃,湿度0.1%RH。工作电流:35mA(

产品详情

Schneider 140HLI34000 是一款中断输入模块,专为工业自动化系统设计。中断输入模块通常用于接收和处理来自各种传感器的输入信号,当这些信号满足特定条件时,会触发中断,从而允许系统对外部事件做出快速响应。

主要特点:

快速响应:该模块能够迅速检测并响应来自传感器的输入信号,确保工业自动化系统能够实时地对外界变化做出反应。

多种输入类型:140HLI34000 支持多种输入类型,如数字输入、模拟输入等,可以适应不同类型的传感器和信号源。

可编程性:模块通常具有可编程功能,用户可以通过配置软件对中断触发条件、响应方式等进行灵活设置。

高可靠性:经过严格的品质控制和工业环境测试,该模块具有高可靠性,能够在恶劣的工业环境下稳定运行。

易于集成:模块设计紧凑,接口标准,易于与其他工业自动化设备和系统进行集成和连接。

应用场景:

在生产线自动化系统中,用于接收和处理来自传感器的信号,实现对生产过程的实时监控和控制。

在机械设备中,用于检测设备的运行状态、故障信息等,及时触发中断并采取相应的处理措施。

在流程控制系统中,用于监测流体流量、液位、温度等参数的变化,当参数超出设定范围时触发中断,确保生产过程的稳定性和安全性。

注意事项:

在选择和使用该模块时,需要确保它与您的工业自动化系统兼容,并了解它的具体规格和参数。

安装和配置时应遵循制造商的指导和建议,确保正确的电源连接和信号接线。

在使用过程中,应定期检查模块的工作状态和响应速度,确保其正常工作并及时处理任何异常情况。

The Schneider 140HLI34000 is an interrupt input module specifically designed for industrial automation systems. Interrupt input modules are typically used to receive and process input signals from various sensors, triggering interrupts when these signals meet certain conditions, allowing the system to respond quickly to external events.

Main features:

Fast response: The module can quickly detect and respond to input signals from sensors, ensuring that industrial automation systems can react to external changes in real time.

Multiple input types: The 140HLI34000 supports a variety of input types, such as digital input, analog input, etc., which can be adapted to different types of sensors and signal sources.

Programmability: The module usually has a programmable function, and the user can flexibly set the interrupt triggering condition and response mode through the configuration software.

High reliability: After strict quality control and industrial environment testing, the module has high reliability and can operate stably in harsh industrial environments.

Easy integration: Compact module design, standard interface, easy to integrate and connect with other industrial automation equipment and systems.

Application scenario:

In the production line automation system, it is used to receive and process signals from sensors to realize real-time monitoring and control of the production process.

In mechanical equipment, it is used to detect the operating status and fault information of the equipment, trigger the interrupt in time, and take corresponding measures.

In the process control system, it is used to monitor the change of fluid flow, liquid level, temperature and other parameters, and trigger interruption when the parameters exceed the set range to ensure the stability and safety of the production process.

Note:

When selecting and using the module, you need to ensure that it is compatible with your industrial automation system and understand its specific specifications and parameters.

Installation and configuration should follow the manufacturer's instructions and recommendations to ensure proper power connections and signal wiring.

In the process of use, the working status and response speed of the module should be checked regularly to ensure that it works normally and to deal with any abnormal situation in time.

相关推荐