手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

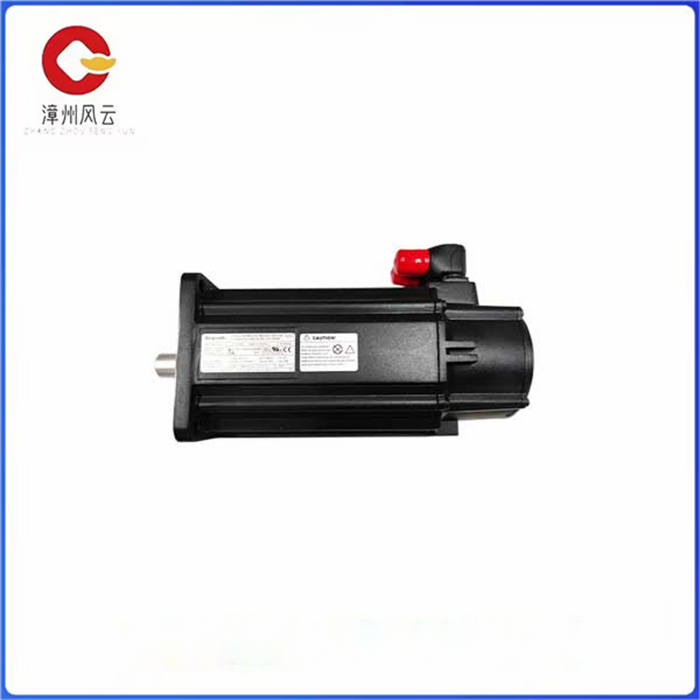

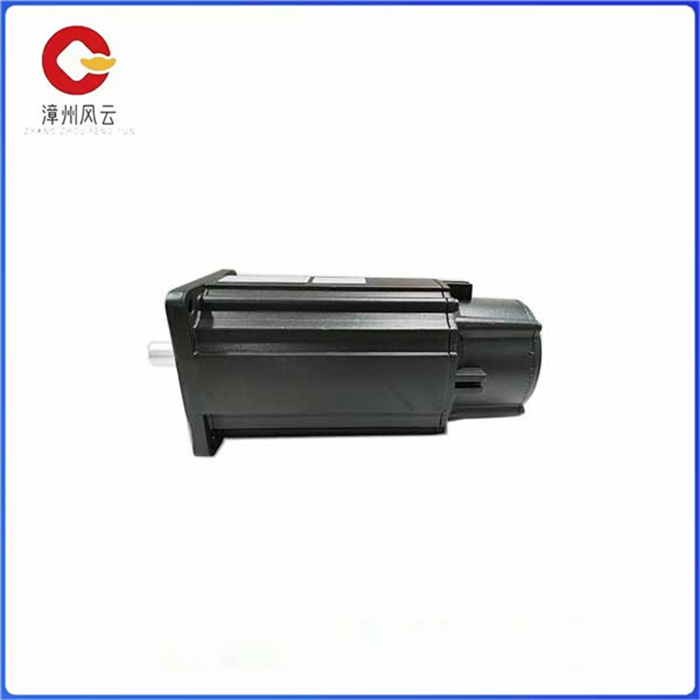

MSK071D-0450-NN-M1-UP1-NNNN力士乐伺服电机品牌力士乐产品特性电机是否进口否产地德国加工定制否工作电压280V输出频率60kHz产品认证

产品详情

力士乐伺服电机是一款高性能的伺服驱动系统,具有高精度、快速响应和低噪声等特点。它采用先进的控制算法和精密的制造工艺,能够实现高精度的位置控制和速度控制,广泛应用于各种自动化设备和工业控制领域。

伺服电机的主要特点包括:

高精度控制:伺服电机采用高精度的编码器来检测电机的转数和位置,从而实现高精度的位置控制和速度控制。

快速响应:伺服电机具有快速的动态响应和调节速度,能够快速跟踪指令信号并做出相应的动作。

低噪声:伺服电机采用低噪声设计和优化的控制算法,能够在低噪声环境下工作,减少对周围环境的影响。

可靠性高:伺服电机采用高品质的材料和优化的结构设计,具有较高的可靠性和稳定性,能够保证长期稳定的工作。

维护方便:伺服电机结构简单、维护方便,一般只需要定期检查和清洁即可保持其良好的工作状态。

在使用伺服电机时,需要注意以下几点:

正确安装:按照制造商的指南正确安装伺服电机,确保其与驱动器和控制系统之间的连接牢固可靠。

定期维护:定期检查伺服电机的运行状态,包括轴承、润滑、散热等方面,确保其正常工作。

防止过载:避免超出伺服电机的额定负载范围使用,以免造成损坏或缩短使用寿命。

控制信号:确保提供给伺服电机的控制信号是正确的,避免过大的电压或电流对电机造成损坏。

环境条件:注意伺服电机的工作环境,包括温度、湿度、振动等方面,确保其处于良好的工作环境中。

Rexroth servo motor is a high performance servo drive system with high precision, fast response and low noise. It adopts advanced control algorithm and precision manufacturing process to achieve high-precision position control and speed control, and is widely used in various automation equipment and industrial control fields.

The main features of servo motor include:

High-precision control: The servo motor uses high-precision encoder to detect the number of revolutions and position of the motor, so as to achieve high-precision position control and speed control.

Fast response: the servo motor has fast dynamic response and adjustment speed, and can quickly track the command signal and make the corresponding action.

Low noise: The servo motor adopts low noise design and optimized control algorithm, which can work in a low noise environment and reduce the impact on the surrounding environment.

High reliability: The servo motor adopts high-quality materials and optimized structural design, which has high reliability and stability, and can ensure long-term stable work.

Easy maintenance: the servo motor has simple structure and easy maintenance, and generally only needs regular inspection and cleaning to maintain its good working condition.

When using the servo motor, the following points need to be noted:

Correct installation: Properly install the servo motor according to the manufacturer's guidelines to ensure a strong and reliable connection to the drive and control system.

Regular maintenance: Regularly check the running status of the servo motor, including bearing, lubrication, heat dissipation, etc., to ensure that it works normally.

Avoid overload: Avoid using beyond the rated load range of the servo motor to avoid damage or shorten the service life.

Control signal: Ensure that the control signal provided to the servo motor is correct to avoid excessive voltage or current damage to the motor.

Environmental conditions: Pay attention to the working environment of the servo motor, including temperature, humidity, vibration, etc., to ensure that it is in a good working environment.

相关推荐