手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

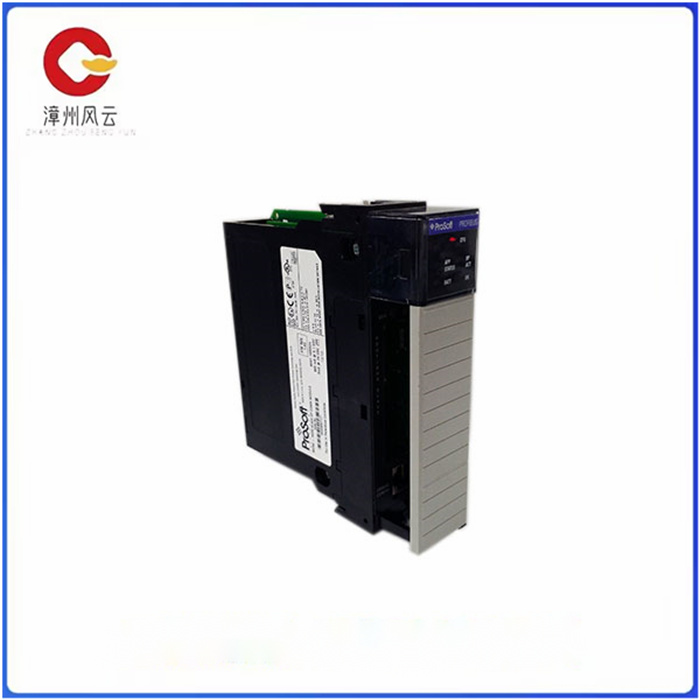

MVI56-PDPS 接口模块 应用PLC系统用于控制复杂的工业品牌PROSOFT产品特性原装保障是否进口否产地欧美加工定制否工作电压标准VV输出频率标准kHz产品认证原厂系列DCS系统PLC模块物料编码69850可售卖地全国型号MVI56-PDPSMVI56-PDPS 接口模块 应用PLC系统用于控制复杂的工业MVI56-PDPS应用PLC系统用于控制复杂的工业过程PROSOFT通讯模块安全仪表

产品详情

MVI56-PDPS应用PLC系统用于控制复杂的工业过程PROSOFT通讯模块安全仪表系统(SIS)旨在通过提供额外的自动化保护来帮助保护人员和资产免受伤害。它们可以用于各种应用,包括制造工艺、化工厂、发电厂和海上钻井作业。通过使系统能够与其他组件和系统通信,软件可以在SIS的运行中发挥重要作用。可以与安全仪表系统集成的常见类型的软件包括人机接口(HMI)、配置管理工具、警报监控工具、分布式控制系统、数据分析工具、预测分析软件和资产跟踪软件。HMI用于显示有关系统性能的信息,并为用户提供系统当前状态的可视化表示。配置管理工具使用户能够轻松准确地更改系统内的设置或参数。

当SIS中检测到潜在问题时,警报监测工具允许自动通知,以便快速采取纠正措施,避免灾难性事件。分布式控制系统有助于确保SIS组件在运行过程中保持佳水平,并保持流程平稳运行。数据分析软件使用户能够识别数据集中的趋势或差异,这些趋势或差异可能表明需要对该工具识别的任何问题的原因进行进一步调查。预测分析软件有助于根据与安全仪表系统相关的历史数据预测未来场景,以便操作员能够主动而非被动地做出明智的决策。资产跟踪软件帮助运营商更快、地进行盘点,同时帮助他们跟踪设备的维护历史,以便在需要时采取适当的预防措施。越来越关注安全:随着更技术的兴起,安全仪表系统在确保生命和设备得到保护方面变得越来越重要。这导致公司越来越重视员工、客户和设施的安全。提高可靠性:技术进步使SIS比以往这使得用户对这些系统的信任度更高。

它们不仅提供了高级别的保护,而且还减少了因系统故障而导致的停机时间。安全系统自动化:安全仪表系统的自动化使其更易于管理和监控,从而降低了运营并提高了效率。这使公司能够在紧急情况下更快地做出反应,同时也减少了与手动操作相关的任何潜在风险经济高效的解决方案:随着技术进步,组件和软件的越来越便宜,安全仪表系统的效益越来越高。这使小型企业能够从这些解决方案中受益,而无需在硬件和培训上进行大量投资。改进的连接性:随着数字技术的进步,系统中不同组件之间的连接性也在提高。这使操作员能够更多地访问实时数据,这些数据可在必要时用于决策或预测性维护措施。改进的性能和安全性:随着安全仪表系统中使用的软件变得越来越复杂,其性能和安全措施也有所改进。这允许更快的响应时间和的数据,减少了与手动操作相关的任何潜在风险。

MVI56-PDPS Applications PLC systems for controlling complex industrial processes PROSOFT Communication Module Safety Instrumentation System (SIS) is designed to help protect people and assets from harm by providing additional automated protection. They can be used in a variety of applications, including manufacturing processes, chemical plants, power plants and offshore drilling operations. By enabling the system to communicate with other components and systems, software can play an important role in the operation of SIS. Common types of software that can be integrated with safety instrumentation systems include human machine interfaces (HMI), configuration management tools, alarm monitoring tools, distributed control systems, data analysis tools, predictive analytics software, and asset tracking software. HMI is used to display information about system performance and provide users with a visual representation of the current state of the system. Configuration management tools enable users to easily and accurately change Settings or parameters within the system.

When a potential problem is detected in SIS, the alert monitoring tool allows automatic notification so that corrective action can be taken quickly to avoid catastrophic events. The distributed control system helps ensure that SIS components are maintained at the best level during operation and keep the process running smoothly. The data analysis software enables users to identify trends or differences in the data set that may indicate the need for further investigation into the cause of any issues identified by the tool. Predictive analytics software helps predict future scenarios based on historical data related to safety instrumentation systems so that operators can make informed decisions proactively rather than passively. Asset tracking software helps operators take inventory faster and faster, while helping them track the maintenance history of their equipment so that appropriate precautions can be taken if needed. Increasing focus on safety: With the rise of more technologies, safety instrumentation systems are becoming increasingly important in ensuring that lives and equipment are protected. This has led to an increased focus on the safety of employees, customers and facilities. Improved reliability: Technological advances have made SIS more reliable than ever before, which has given users greater trust in these systems.

Not only do they provide a high level of protection, but they also reduce downtime due to system failures. Automation of safety systems: Automation of safety instrumentation systems makes them easier to manage and monitor, resulting in reduced operations and increased efficiency. This allows the company to respond faster in emergency situations, while also reducing any potential risks associated with manual operation Cost-effective solutions: As technology advances and components and software become cheaper, safety instrumentation systems become more and more efficient. This enables small businesses to benefit from these solutions without having to make significant investments in hardware and training. Improved connectivity: As digital technology advances, so does the connectivity between the different components in the system. This gives operators greater access to real-time data that can be used for decision-making or predictive maintenance measures when necessary. Improved performance and safety: As the software used in safety instrumentation systems has become more complex, its performance and safety measures have also improved. This allows for faster response times and data, reducing any potential risks associated with manual operations.

相关推荐