手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

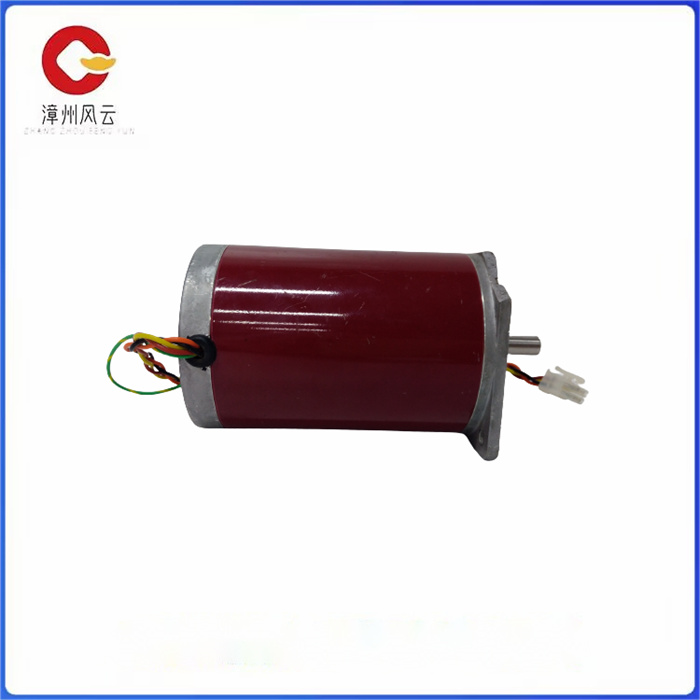

E33NRHA-LNN-NS-00标准的IIoT边缘计算网关品牌原装进口风速10km/h售后质保一年重量2.4lb功率120VDC频率1020Hz通道8通道温度

产品详情

E33NRHA-LNN-NS-00 可以经过多种方式增强进程操控。新式自动化体系的根本PID操控算法比前期体系更为精细,响应速度更快,可提高一切规范PID回路的操控。PID回路的自整定一般是内置的,然后可为整定参数供给更好的初始值,还有助于不断进行调整和改进。

除根本PID算法外,现代化的自动化体系还包含其它调理操控选项,例如增强型PID和用户自定义指令。增强型PID采用PID等式的速度型算法,即回路经过偏差的改变来更改输出。用户自定义指令(由用户创立的自定义指令)用于封装常用的功能或设备操控。

新式自动化体系还具有基于模型的功能块和模糊逻辑等内置的高档进程操控(APC)功能。这些功能可用于创立用户自己的APC应用程序。这些工具的关键组件是规范的自定义功能块,可使用多种办法将它们互连来开发APC应用程序。将规范和自定义APC功能块相结合,用户就可以操控无法经过简略PID或其它调理操控办法(例如,增强型PID或用户自定义指令)调理到可接受水平的回路。

与前期DCS比较,新式自动化体系具有增强的报警和事情处理功能。这可提高操作员绩效,并为负责工厂运营剖析和绩效提高的工程师供给更有价值的数据。

对报警处理的改进包含可以排定报警优先顺序,然后削减报警众多并更易于确定报警的根本原因。工厂人员可使用带时刻戳的报警和事情详细列表剖析进程搅扰和其它反常情况。经过此类剖析,可以更快速地确定根本原因,便于维护人员从源头纠正问题。

新式自动化体系还答应非编程人员创立各种报表,以简略易懂的格局供给数据。简略易懂的报表有助于更好地了解工厂绩效,更利于改进运营。使用前期DCS创立报表一般好不容易。

性能方面,与前期DCS比较,新式自动化体系可削减故障的发生。此外,供应商会不断为其的自动化体系产品增加新的特性和功能,而这些新增内容(特别是软件相关的升级)一般可以乃至免费获取。

The E33NRHA-LNN-NS-00 can enhance process manipulation in a variety of ways. The fundamental PID control algorithm of the new automation system is more refined than that of the previous system, and the response speed is faster, which can improve the control of all the normal PID circuits. The self-tuning of the PID loop is generally built-in, which then provides better initial values for the tuning parameters, and also facilitates continuous adjustment and improvement.

In addition to the basic PID algorithm, the modern automation system includes other conditioning control options, such as enhanced PID and user-defined instructions. The enhanced PID uses the speed algorithm of the PID equation, that is, the loop is changed by deviation to change the output. User-defined instructions (custom instructions created by users) are used to encapsulate commonly used functions or device controls.

The new automation system also has built-in advanced process control (APC) functions such as model-based functional blocks and fuzzy logic. These features can be used to create a user's own APC application. The key components of these tools are canonical custom functional blocks that can be interlinked in a variety of ways to develop APC applications. The combination of specification and custom APC functional blocks allows users to control loops that cannot be conditioned to an acceptable level by a simplified PID or other conditioning control methods (e.g., enhanced PID or user-defined instructions).

Compared with the previous DCS, the new automation system has enhanced alarm and event processing functions. This improves operator performance and provides more valuable data to engineers responsible for plant operational profiling and performance improvement.

Improvements to alarm handling include the ability to prioritize alarms, then reduce the number of alarms and make it easier to determine the root cause of alarms. Factory personnel can use time-stamped alerts and event detailed lists to parse process disturbances and other anomalies. With such profiling, root causes can be identified more quickly and maintenance personnel can correct problems at the source.

The new automation system also allows non-programmers to create reports that provide data in an easy-to-understand format. Simple, easy-to-understand reports help you better understand plant performance and improve operations. It is generally not easy to create reports using previous DCS.

In terms of performance, compared with the previous DCS, the new automation system can reduce the occurrence of faults. In addition, vendors are constantly adding new features and capabilities to their automation system products, and these additions (especially software-related upgrades) are often available or even free of charge.

相关推荐