手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

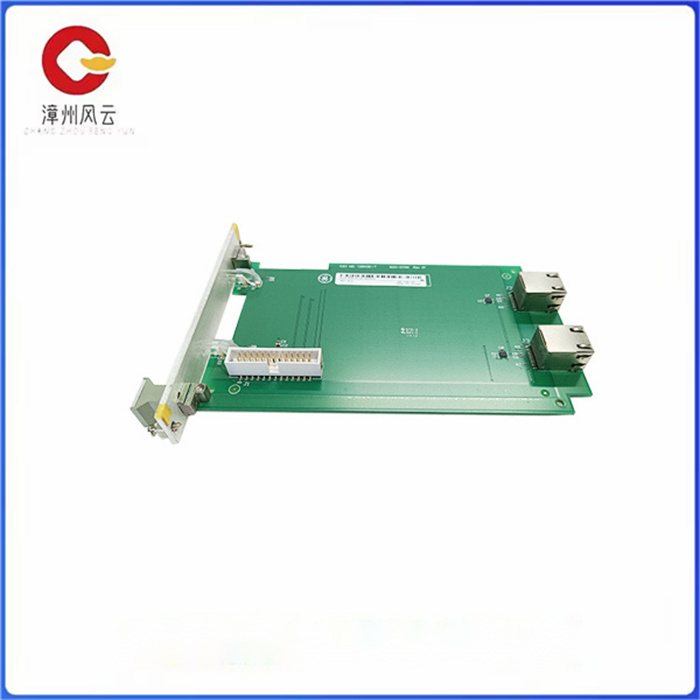

D20MIC10BASE-T可控硅模块具有多种保护功能品牌GE是否进口是颜色绿色其它型号12HGA11J52电压180重量1.6kg产地美国质保两年环境正常是否

产品详情

GE D20 MIC 10BASE-T是一种工业触摸显示器。它通常用于工业自动化和控制系统,具有触摸屏功能,可以接收用户的触摸信息并将其转换为触点坐标,再送给CPU进行处理。同时,它还具有多种保护功能,如过压保护、过流保护、短路保护等,以确保系统的稳定性和安全性。

包括可编程逻辑控制器(PLCS),交流驱动器/电动机,操作者接口面板/HMI,电机控制,直流电源,按钮,传感器,NeMA电器罩,电线管道等。公司以令人难以置信的价格提供高质量的自动化产品,并提供详细的文档资料、优质的销售和技术支持。

系统具有61131-3功能,并确保了OPC的通信安全,"SOA(面向服务的体系结构)PLC为实施"智能工厂"、行业4.0和物联网(iot)提供高效、数据一致、安全和标准化的通信。该模块的服务直接相互沟通,并要求产品自我控制,而不是从企业资源规划系统中通过教育和科学部、PLC进行"自上而下"的通信,最终到达传感器。测量设备、传感器、rfid芯片、PLCS和其他嵌入式系统为工业应用中的生产提供了重要的数据。在传统的控制体系结构中,数据请求是循环启动的,或者是事件引发的,总是响应"来自上面"的请求,即。从客户端开始。较低级别总是充当服务器并相应响应。换句话说,rfid阅读器或PLC控制器在通信方面并不"智能"。在智能工厂中,实体的、真实的系统和虚拟的、数字的数据合并成智能的、自组织的生产单元。他们自主获取为此目的所需的数据。这意味着所有设备和服务都必须能够独立地相互通信,而不论制造商、操作系统、层次结构或拓扑结构。

The GE D20 MIC 10BASE-T is an industrial touch display. Commonly used in industrial automation and control systems, it has a touch screen function that can receive the user's touch information and convert it into contact coordinates, which are then sent to the CPU for processing. At the same time, it also has a variety of protection functions, such as overvoltage protection, overcurrent protection, short circuit protection, etc., to ensure the stability and safety of the system.

Includes Programmable logic controller (PLCS), AC driver/motor, operator interface panel /HMI, motor control, DC power supply, buttons, sensors,NeMA appliance cover, wire piping, etc. The company offers high quality automation products at incredible prices, with detailed documentation, excellent sales and technical support.

The system is 61131-3 functional and ensures communication security for OPC,"SOA(Service Oriented Architecture)PLC provides efficient, data consistent, secure and standardized communication for implementing "smart factories", Industry 4.0 and the Internet of Things (iot). The module's services communicate directly with each other and require product self-control, rather than "top-down" communication from the enterprise resource planning system through the Education and Science Department, the PLC, and ultimately to the sensor. Measuring devices, sensors, rfid chips, PLCS and other embedded systems provide important data for production in industrial applications. In a traditional control architecture, data requests are loop-initiated, or event-initiated, always in response to requests "from above", i.e. Start with the client. The lower level always acts as the server and responds accordingly. In other words,rfid readers or PLC controllers are not "smart" in terms of communication. In a smart factory, physical, real systems and virtual, digital data are combined into intelligent, self-organizing production units. They acquire the data they need for this purpose autonomously. This means that all devices and services must be able to communicate with each other independently, regardless of manufacturer, operating system, hierarchy, or topology.

相关推荐