手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

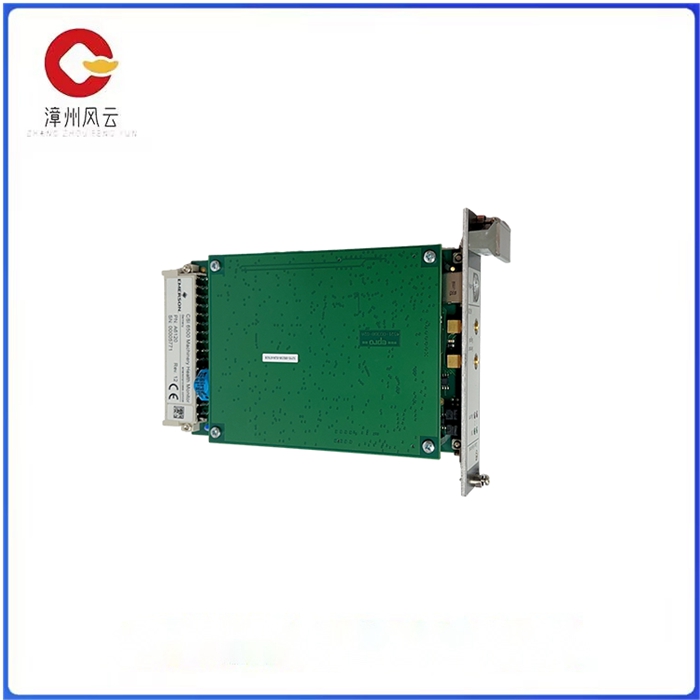

A6120输入输出模块数字信号线的屏蔽层应并联EMERSONA6120输入输出模块信号传输通常,当模拟输入输出信号距PLC较远时,应采用4-20ma或0-10m

产品详情

EMERSON A6120 输入输出模块信号传输通常,当模拟输入输出信号距PLC较远时,应采用4-20ma或0-10ma的电流传输方式,而不是电压传送方式。传送模拟信号的屏蔽层为一端接地。为了泄放高频干扰,数字信号线的屏蔽层应并联电位均衡线,并将屏蔽层两端接地。

扩展模块的选用:80点以内的系统,一般不需要扩展,当系统较大时就要扩展。当扩展不能满足要求时,可采用网络结构。

扩展模块种类很多,如单输入模、单输出模块、输入输出模块、温度模块、高速输入模块等。PLC的网络设计:用PLC进行网络设计难度比PLC单机控制大得多。

EMERSON A6120 输入输出模块首先应先用自己较熟悉的机型,对其基本指令和功能指令有较深入的了解,并且指令的执行速度和用户程序存储容量也应仔细了解。否则,不能适应实时要求,造成崩溃。另外,还要考虑通信接口、通信协议、数据传送速度等。最后,还要向商家寻求网设计和软件技术支持及详细技术资料。

软件编制:在编制软件前,应首先熟悉所先用的PLC产品软件说明书。若用图形编程器或软件包,则可直接编程,若用手持编程器编程,应先画出梯形图后再编程。编程结束后先空调程序,待各个动作正常后,再在设备上调试。

In general, when the analog input and output signals are far away from the PLC, the current transmission mode of 4-20ma or 0-10ma should be used instead of the voltage transmission mode. The shielding layer for transmitting the analog signal is grounded at one end. In order to relieve high-frequency interference, the shielding layer of the digital signal line should be parallel to the potential equalization line, and the two ends of the shielding layer should be grounded.

Expansion module selection: the system within 80 points, generally do not need to expand, when the system is larger to expand. When the expansion cannot meet the requirements, the network architecture can be used.

There are many types of expansion modules, such as single input mode, single output module, input/output module, temperature module, high-speed input module and so on. PLC network design: Using PLC network design is much more difficult than PLC single machine control.

EMERSON A6120 input/output module should first use their own familiar model, have a deeper understanding of its basic instructions and functional instructions, and command execution speed and user program storage capacity should also be carefully understood. Otherwise, it cannot meet the real-time requirements, resulting in a crash. In addition, also consider the communication interface, communication protocol, data transmission speed and so on. Finally, it is also necessary to seek network design and software technical support and detailed technical information from businesses.

Software preparation: Before the preparation of software, you should first be familiar with the PLC product software manual. If you use a graphic programmer or software package, you can program directly, if you use a handheld programmer programming, you should draw a ladder diagram before programming. After the programming is finished, the air conditioning program is first, and after each action is normal, it is debugged on the equipment.

相关推荐