手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

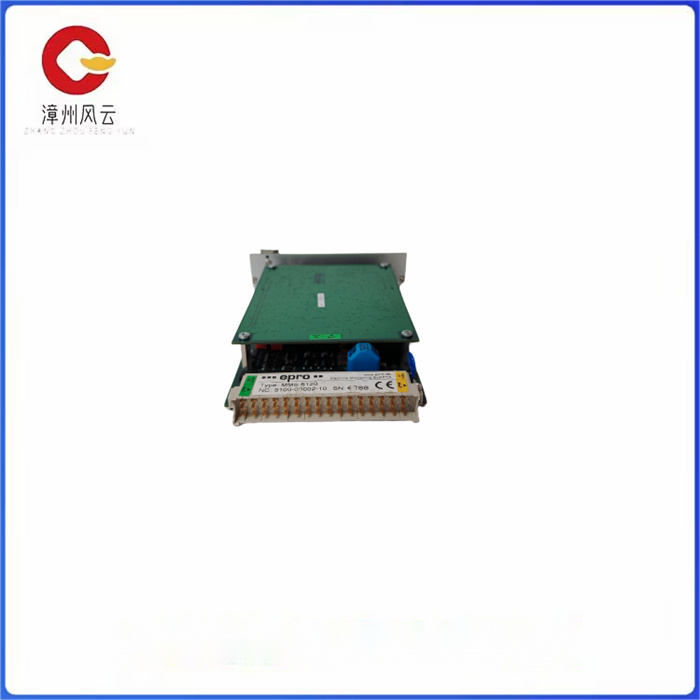

MMS6120轴振瓦振位移偏心检测板件模块膨胀转速品牌EPRO艾默生系统环境自动化输出电流15A重量10KGAO个数10组物料编号1523运送方式物流防护等级I

产品详情

模块的设计满足通用的国际标准,如: API670、VDI2056、 VDI2059。 这种模块的测量可以和其它模块的测量一起组成涡轮机械保护系统,以及作为输入提供给分析诊断系统、现场总线系统、分散控制系统、电厂/主计算机、网络如: WAN/LAN网、以太网。

对于蒸汽机、燃汽机、水轮机、压缩机、风扇、离心机以及其它涡轮机械,使用本系统可提高使用效率、运行安全性和延长机械使用寿命。MMS6120为双通道轴承振动测量模块,可以用电动式速度传感器测量轴承振动(瓦振)来监测和保护各种类型的涡轮机械,如:汽轮机、燃汽轮机、压缩机、风扇、齿轮箱、鼓风机、离心机等。安装在轴瓦上的传感器的输出信号与轴瓦的*振动成正比MMS6120模块将两个通道的传感器输入信号分别转换成标准信号输出。模块的其它部分提供报警、传感器供电、模块供电、通道和传感器的检测及信号滤波等功能。模块内置微处理器,可以通过现场便携机或远程通讯总线设置工作方式和参数,读取所有测量值,进行频谱分析。后- -次起/停机过程存储在模块中,可以通过计算机显示。

基本功能

数据缓冲:由于I/0设备的速率较低而CPU和内存的速率却很高,故在控制器中必须设置一缓冲器。在输出时,用此缓冲器暂存由主机高速传来的数据,然后才以1/0设备所具有的速率将缓冲器中的数据传送给1/0设备;在输入时,缓冲器则用于暂存从1/0设备送来的数据,待接收到一批数据后,再将缓冲器中的数据高速地传送给主机。

差错控制:设备控制器还兼管对由1/0设备传送来的数据进行差错检测。若发现传送中出现了错误,通常是将差错检测码置位,并向CPU报告,于是CPU将本次传送来的数据作废,并重新进行一次传送。这样便可保证数据输入的正确性。数据交换:这是指实现CPU与控制器之间、控制器与设备之间的数据交换。对于前者,是通过数据总线,由CPU并行地把数据写入控制器,或从控制器中并行地读出数据;对于后者,是设备将数据输入到控制器,或从控制器传送给设备。为此,在控制器中须设置数据寄存器

Modules are designed to meet common international standards such as API670, VDI2056, VDI2059. Measurements of this module can be combined with measurements of other modules to form turbomachinery protection systems, as well as provided as input to analytical diagnostic systems, fieldbus systems, decentralized control systems, power plants/main computers, networks such as WAN/LAN networks, and Ethernet.

For steam engines, gas engines, water turbines, compressors, fans, centrifuges and other turbo-machinery, the use of this system can improve the efficiency, operation safety and prolong the service life of the machinery. The MMS6120 is a two-channel bearing vibration measurement module that can be used to measure bearing vibration (tilting vibration) with an electric speed sensor to monitor and protect various types of turbine-machinery such as steam turbines, gas turbines, compressors, fans, gearboxes, blowers, centrifuges, etc. The output signal of the sensor mounted on the bearing bush is proportional to the * vibration of the bearing bush. The MMS6120 module converts the sensor input signal of the two channels into the standard signal output respectively. Other parts of the module provide alarm, sensor power supply, module power supply, channel and sensor detection and signal filtering functions. The module has a built-in microprocessor, which can set the working mode and parameters through the field portable computer or the remote communication bus, read all the measured values, and perform spectrum analysis. The post-start/stop process is stored in the module and can be displayed via the computer.

Basic function

Data buffering: Because the I/0 device speed is low and the CPU and memory speed is high, a buffer must be set in the controller. When output, the buffer is used to temporarily store the data from the host at high speed, and then the data in the buffer is transmitted to the 1/0 device at the rate that the 1/0 device has; During input, the buffer is used to temporarily store the data sent from the 1/0 device, and after receiving a batch of data, the data in the buffer is transmitted to the host at high speed.

Error control: The device controller is also responsible for error detection of data transmitted by the 1/0 device. If an error is found in the transmission, the error detection code is usually set and reported to the CPU, so the CPU will cancel the data sent this time and retry the transmission. This ensures the correctness of data input. Data exchange: This refers to the realization of data exchange between the CPU and the controller, and between the controller and the device. For the former, through the data bus, the CPU writes the data to the controller in parallel, or reads the data from the controller in parallel; In the latter case, the device inputs data to the controller, or from the controller to the device. For this purpose, a data register must be set up in the controller

相关推荐