手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

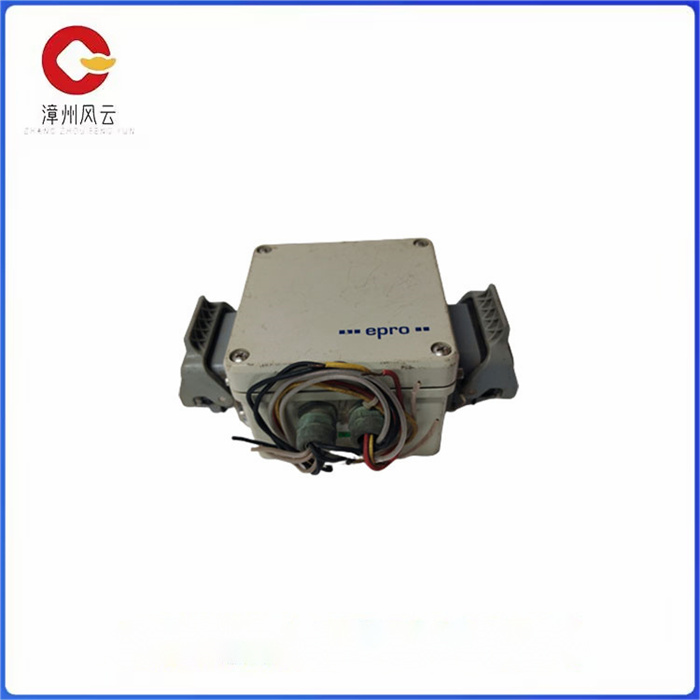

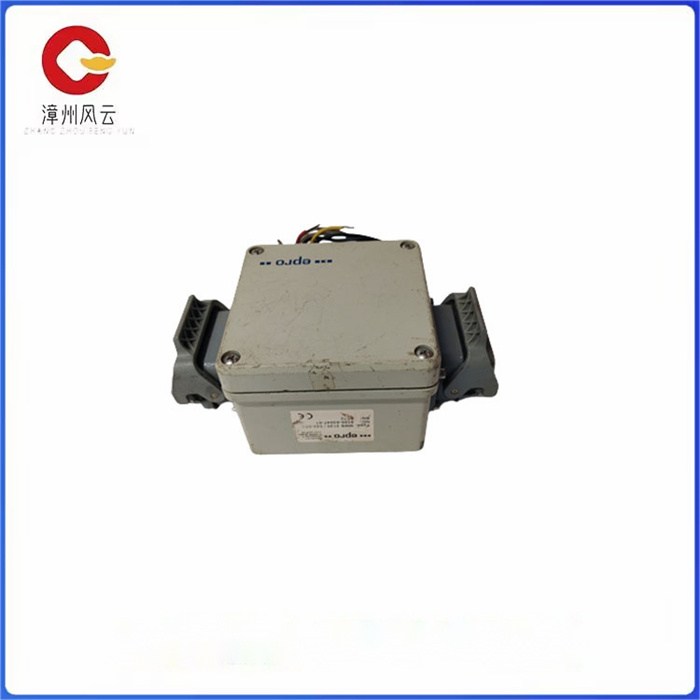

MMS3120022-0009100-03047-01轴承振动变送器品牌EPRO规格567*464颜色米色特点变送器加工定制否物料编码9100-03047-01

产品详情

产品详情:

EPRO MMS3120/022-000(9100-03047-01)是一种轴承振动变送器,通常用于监测机械设备中轴承的振动和状态。这种变送器可以检测机械设备的振动水平,以便在振动异常或故障发生时提前采取维护措施。以下是一些可能的特点和应用:

特点:

振动检测:MMS3120/022-000 变送器用于检测机械设备中的振动水平,包括振动的振幅、频率和波形。

状态监测:它可以监测轴承的状态,包括轴承的温度、润滑油条件和振动异常。

数据输出:该变送器通常提供振动数据的输出,以便连接到数据采集系统或监控设备,以进行实时监测和分析。

警报和报警:当振动水平或轴承状态超出预定的阈值时,该变送器通常能够触发警报或报警,以提醒操作人员采取适当的行动。

可靠性:它通常设计用于工业环境,以确保可靠性和耐用性。

应用领域:

工业机械:MMS3120/022-000 轴承振动变送器通常用于各种工业机械设备,包括泵、风机、电机、压缩机和旋转设备。

设备维护:用于设备维护,以预防机械设备故障和减少停机时间。

监测系统:在设备监测系统中使用,以实时监测振动和轴承状态,以进行数据采集和分析。

安全和可靠性:有助于确保设备的安全性和可靠性,防止意外故障和损坏。

预测性维护:支持预测性维护策略,以降低维护成本和提高设备寿命。

Product Details:

EPRO MMS3120/022-000 (9100-03047-01) is a bearing vibration transmitter commonly used to monitor the vibration and condition of bearings in mechanical equipment. This transmitter can detect the vibration level of mechanical equipment so that maintenance measures can be taken in advance if abnormal vibration or failure occurs. Here are some possible features and applications:

Features:

Vibration detection: The MMS3120/022-000 transmitter is used to detect vibration levels in mechanical equipment, including vibration amplitude, frequency and waveform.

Condition monitoring: It can monitor the status of bearings, including bearing temperature, lubricating oil conditions and vibration anomalies.

Data output: This transmitter typically provides an output of vibration data for connection to a data acquisition system or monitoring device for real-time monitoring and analysis.

Alarm and alarm: When the vibration level or bearing status exceeds a predetermined threshold, the transmitter is usually capable of triggering an alarm or alarm to alert the operator to take appropriate action.

Reliability: It is usually designed for use in industrial environments to ensure reliability and durability.

Application field:

Industrial machinery: MMS3120/022-000 bearing vibration transmitters are commonly used in a variety of industrial machinery equipment, including pumps, fans, motors, compressors and rotating equipment.

Equipment maintenance: Used for equipment maintenance to prevent mechanical equipment failures and reduce downtime.

Monitoring system: Used in equipment monitoring systems to monitor vibration and bearing status in real time for data acquisition and analysis.

Safety and reliability: helps to ensure the safety and reliability of equipment to prevent accidental failure and damage.

Predictive Maintenance: Support predictive maintenance strategies to reduce maintenance costs and increase equipment life.

相关推荐