手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@fyplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

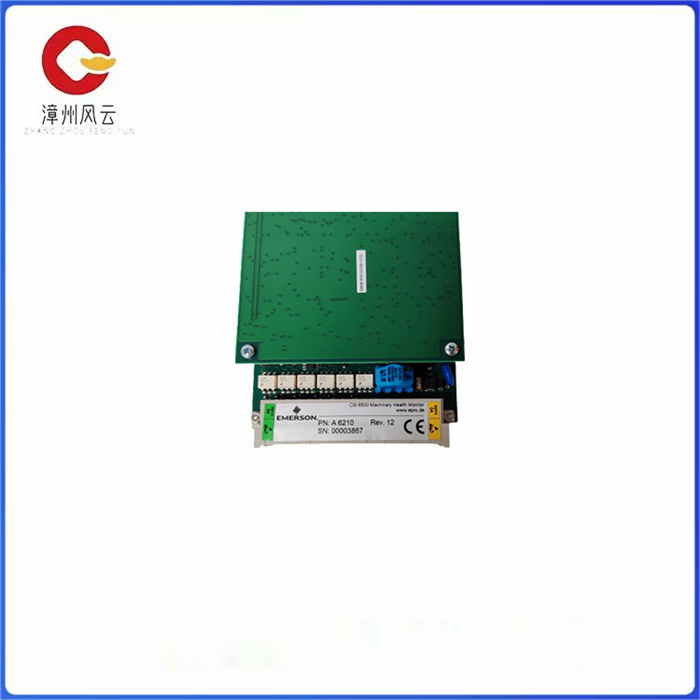

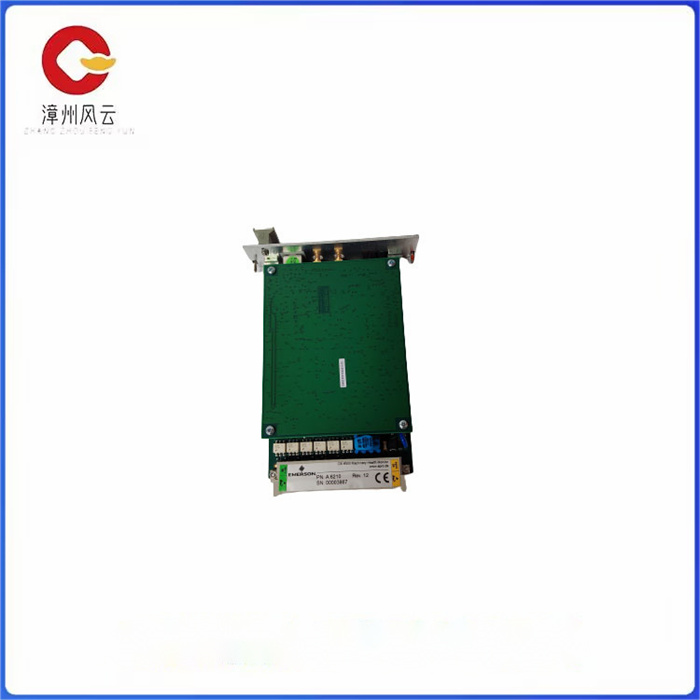

A6210Emerson监测电源模块轴振监测卡品牌艾默生产品特性***原装是否进口否产地美国加工定制否工作电压标准VV输出频率标准kHz产品认证原厂标准系列艾默

产品详情

振动是反映机械设备运行状态的重要参数,当设备发生故障时(例如零部件之间的变形、碰撞、摩擦、破损等),其振动状态产生变化,通过振动监测系统对设备振动进行监测,分析提取振动信号中的故障特征,可以判断设备的健康状态,进行故障诊断和预测。

A6210 EMERSON振动监测具有以下特点:

1)包含故障信息丰富。设备中主要零部件的各种典型损耗性故障都可以通过振动监测做出诊断。

2)故障反应灵敏、迅速。振动对故障反映比较灵敏,即使非常微弱的故障,也会引起振动变化。通过各种振动信号分析处理方法可以在强干扰背景下提取故障信息,因此可以实现故障的早期诊断。

3)A6210 EMERSON测量方便。只要将振动传感器安装在设备体上的合适部位,即可实现振动测量,对设备不产生影响。

本篇首先介绍振动监测的相关标准,其次,通过以齿轮减速机及轴承为对象,介绍振动监测的理论基础。

一、振动监测的标准

A6210 EMERSON机器设备的健康状态是保障其长期安全可靠运行的基本条件,振动大小是反映机器设备健康状态的主要指标之一。在当前技术水平下,国内外针对大型、重要设备通常都采取了振动监测手段,包括在线或离线监测,通过监测设备的振动判断设备的健康状态。为了描述机器的健康状态,必须根据法定的标准作为评定准则。对于机器设备的制造厂来说,标准是确定产品是否合格的依据;而对于机器设备的使用单位来说,特别是使用中的一些大型设备或流程工业中的关键设备,标准也是随时掌握设备运行状态的依据。国际标准化组织(ISO)下设的振动、冲击与状态监测技术委员会(TC108)是专门负责制定振动与冲击方面国际标准的机构,A6210 EMERSON该机构根据机械设备状态监测和故障诊断技术发展的需要,还归口制定机器状态监测和故障诊断方面的国际标准。我国与ISO/TC 108对口的是全国机械振动、冲击及状态监测标准化技术委员会(SAC/TC53),该委员会由国家有关部委专家共同组成,是全国性专业标准化技术工作组织,由国家质量监督检验检疫总局领导。

Vibration is an important parameter that reflects the operating state of mechanical equipment. When the equipment fails (such as deformation, collision, friction, damage, etc.), its vibration state changes. The vibration monitoring system is used to monitor the vibration of the equipment, analyze and extract the fault characteristics in the vibration signal, so as to judge the health state of the equipment, diagnose and predict the fault.

A6210 EMERSON Vibration monitoring features:

1) Contains abundant fault information. Typical lossmaking faults of major components in the equipment can be diagnosed by vibration monitoring.

2) Sensitive and rapid fault response. Vibration is sensitive to faults, and even very weak faults can cause vibration changes. Through various vibration signal analysis and processing methods, the fault information can be extracted under strong interference background, so the early fault diagnosis can be realized.

3) A6210 EMERSON Easy to measure. As long as the vibration sensor is installed in the appropriate part of the equipment body, the vibration measurement can be achieved without affecting the equipment.

This paper first introduces the relevant standards of vibration monitoring, and secondly, introduces the theoretical basis of vibration monitoring by taking gear reducer and bearing as the object.

1. Standards for vibration monitoring

The health of the A6210 EMERSON equipment is the basic condition to ensure its long-term safe and reliable operation, and vibration is one of the main indicators of the health of the equipment. At the current level of technology, vibration monitoring means are usually adopted for large and important equipment at home and abroad, including online or offline monitoring, and the health status of the equipment is judged by the vibration of the monitoring equipment. In order to describe the health state of the machine, it is necessary to use statutory standards as assessment criteria. For the manufacturer of machine equipment, the standard is the basis for determining whether the product is qualified; For the use of machinery and equipment units, especially some large equipment in use or key equipment in the process industry, standards are also the basis for mastering the operating status of equipment at any time. The Technical Committee on Vibration, Shock and Condition Monitoring (TC108) of the International Organization for Standardization (ISO) is the body responsible for the development of international standards on vibration and shock, A6210 EMERSON according to the needs of the development of condition monitoring and fault diagnosis technology of machinery and equipment. International standards for machine condition monitoring and fault diagnosis are also developed centrally. China's counterpart to ISO/TC 108 is the National Mechanical vibration, shock and condition monitoring standardization Technical Committee (SAC/TC53), which is composed of experts from relevant ministries and commissions of the State, is a national professional standardization technical work organization, led by the State General Administration of Quality Supervision, Inspection and Quarantine.

相关推荐