手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

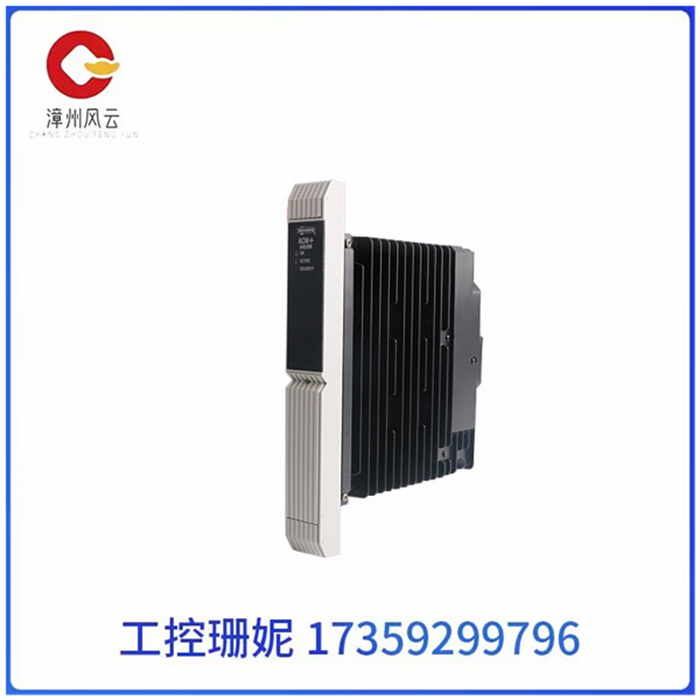

VE4014 ROSEMOUNT DELTA V-I/O单元尺寸450*450重量1kg加工定制否布局形式广泛加工精度98%新旧程度全新配件名称阀门是否原厂是颜色灰白产地德国包装纸箱电流交流电可售卖地全国用途电厂VE4014 ROSEMOUNT DELTA V-I/O单元用于完成对加热炉的热工控制和过程参数检测。该系统的处理器1757p1*52a是rockwell专用处理器,具有8mram,高速底

产品详情

VE4014 ROSEMOUNT DELTA V-I/O单元

VE4014 ROSEMOUNT DELTA V-I/O单元

用于完成对加热炉的热工控制和过程参数检测。该系统的处理器1757p1*52a是rockwell专用处理器,具有8mram,高速底板与网络融为一体,i/o模块可带电插拨,并可以任意安排。

在该系统中,控制站共设有1个主机架和2个扩展机架,完成了整个加热炉的6段温度控制、60多点的模拟量检测及20多个开关量的输入和输出。系统模板采用如下:4个756 of6ci/a模块、9个1756ib16d/ a模块、2个1756ow16i模块、4个1756if6i/a模块、5个1756ir6i/a模块、4个1756it6i/a模块。为提高本系统的可靠量,所有ai、di和do均与现场进行了隔离,ai模板还选用了通道和通道间均有隔离的双隔离模板。

按照确定的控制规则进行编程,根据加热炉的工况选择使用。将现场信号采样﹑燃气流量模糊控制回路﹑空气流量模糊控制回路﹑温度模糊控制回路编成子程序,模块化,在主程序中调用,以利于调试和控制功能组态。该网络属于无源的高性能多元总线,5m的传输速度。数据传输采用确定性的传输方式,大大减少了数据传输量,现场仪表控制阀采用耐高温的控制阀,执行机构采用气动执行机构,压力和差压变送器采用fisher 3051变送器。

VE4014 ROSEMOUNT DELTA V-I/O单元

It is used to complete the thermal control and process parameter detection of the heating furnace. The system's 1757p1*52a processor is a Rockwell-specific processor with 8mram, a high-speed backboard integrated with the network, and i/o modules can be plugged in and out, and can be arranged arbitrarily.

In this system, the control station is equipped with one main frame and two extension frames, which can control the temperature of the whole heating furnace in 6 stages, detect the analog quantity of more than 60 points and input and output of more than 20 switching quantities. The system template consists of four 756 of6ci/a modules, nine 1756ib16d/ a modules, two 1756ow16i modules, four 1756if6i/a modules, five 1756ir6i/a modules, and four 1756it6i/a modules. In order to improve the reliability of the system, all ai, di and do are isolated from the field, and the ai template also uses a dual isolation template with isolation between channels and channels.

According to the established control rules of programming, according to the condition of the heating furnace to choose the use. The sampling of field signal, fuzzy control loop of gas flow, fuzzy control loop of air flow and fuzzy control loop of temperature are modularized and called in the main program to facilitate debugging and control function configuration. The network is a passive high performance multi-component bus with a transmission speed of 5m. Data transmission adopts deterministic transmission mode, which greatly reduces the amount of data transmission. The field instrument control valve adopts high-temperature control valve, the actuator adopts pneumatic actuator, and the pressure and differential pressure transmitter adopts fisher 3051 transmitter.

相关推荐