手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

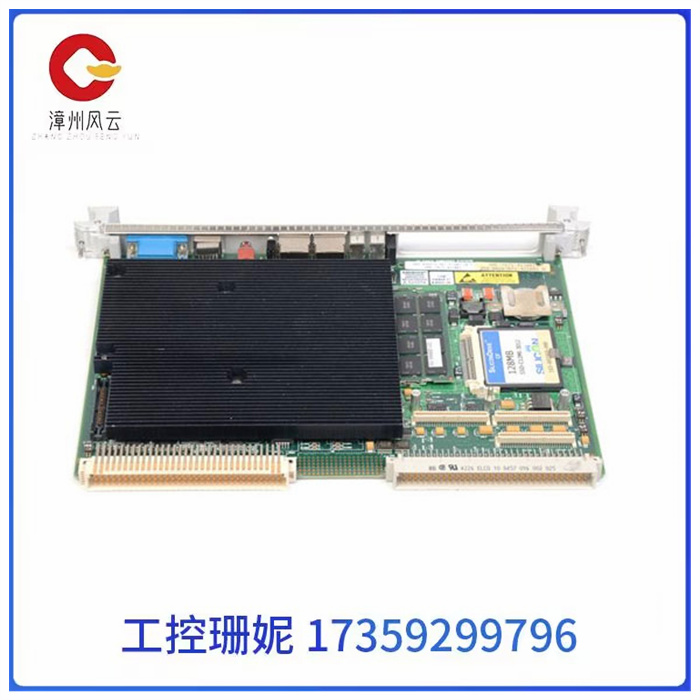

LAM电路板605-048878-001 VME-7671-421000半导体配件资源品牌LAM批号库存封装拆机包装散装最小包装量1料号VME7671数量1质保包好可售卖地全国类型电路板型号605-048878-001LAM电路板605-048878-001 VME-7671-421000半导体配件资源工业机器人控制策略发展趋势 到目前为止, 多数商品化工业机器人控制器下级 的控制策略基本上是独立

产品详情

LAM电路板605-048878-001 VME-7671-421000半导体配件资源

LAM电路板605-048878-001 VME-7671-421000半导体配件资源

工业机器人控制策略发展趋势 到目前为止, 多数商品化工业机器人控制器下级 的控制策略基本上是独立关节 PID伺服算法。

这种控 制方法的主要缺点是, 反馈增益是预先确定的常量, 它不能在有效载荷变化的情况下改变反馈增益。机器 人高速运动时, 其动力学效应十分 为解决上述 & 96& 机床与液压 第 36卷 问题, 就要根据机器人手臂的动态模型求出施加于机 器人手臂的力矩。于是就提出了诸如计算力矩法、非 线性解耦反馈控制、前馈补偿控制算法等方案。

但这 些算法大多过于复杂, 难以实时计算。故研究人员一 方面研究简化模型、简化计算方法, 提出一些 并行算法、递推算法等; 另一方面又研究对系统参数 变化及扰动不敏感, 或不过分依赖准确的系统动态模 型的控制方法。后, 充分考虑各控制算法的优缺 点, 取长补短, 在一个工业机器人当中采用多种控制 算法的结合处理。开展对控制方案、动态控制模型以 及控制算法的研究, 以求改善机器人系统的动态控制 性能。工业机器人控制策略主要向以下 3个方面发 展。 2\u00011 力位置混合控制 工业机器人在实际应用中都不可避免地要与环境 接触, 比如生产装配、焊接等 , 它们 是简单的 位置控制, 而需要机械手具有感觉和触觉, 将面临更 多的不确定性, 故力和位置混合控制将成为未来工业 机器人控制的一个研究方向

LAM电路板605-048878-001 VME-7671-421000半导体配件资源

So far, the control strategy of most commercial industrial robot controllers is basically an independent joint PID servo algorithm.

The main disadvantage of this control method is that the feedback gain is a predetermined constant, and it cannot change the feedback gain in the case of payload changes. When the robot moves at high speed, its dynamic effect is very important to solve the above &96 & machine tool and hydraulic volume 36 problem, it is necessary to calculate the torque applied to the robot arm according to the dynamic model of the robot arm. Therefore, some schemes such as calculating moment method, non-linear decoupling feedback control, feedforward compensation control algorithm are proposed.

But most of these algorithms are too complex to calculate in real time. Therefore, on the one hand, researchers study the simplified model, simplified calculation methods, and propose some parallel algorithms and recursive calculation methods. On the other hand, the control methods that are not sensitive to the change of system parameters and perturbations, or not overly dependent on accurate system dynamic modes, are studied. Finally, the advantages and disadvantages of each control algorithm are fully considered, and the combination of various control algorithms is adopted in an industrial robot. The control scheme, dynamic control model and control algorithm are studied in order to improve the dynamic control performance of robot system. Industrial robot control strategies are mainly developed in the following three aspects. 2\u00011 force position hybrid control industrial robots in practical applications are inevitably in contact with the environment, such as production assembly, welding, etc., they are simple position control, and the need for the manipulator to have a sense and touch, will face more uncertainty, Therefore, the hybrid control of force and position will become a research direction of industrial robot control in the future

相关推荐