手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

0-57435 模块在可编程逻辑控制器系统设计时,首先应确定控制方案,下一步工作就是可编程逻辑控制器工程设计选型。工艺流程的特点和应用要求是设计选型的主要依据。可编程逻辑控制器及有关设备应是集成的、标准的,按照易于与工业控制系统形成一个整体,易于扩充其功能的原则选型所选用可编程逻辑控制器应是在相关工业领域有投运业绩、成熟可靠的系统,可编程逻辑控制器的系统硬件、软件配置及功能应与装置规模和控制要求相

产品详情

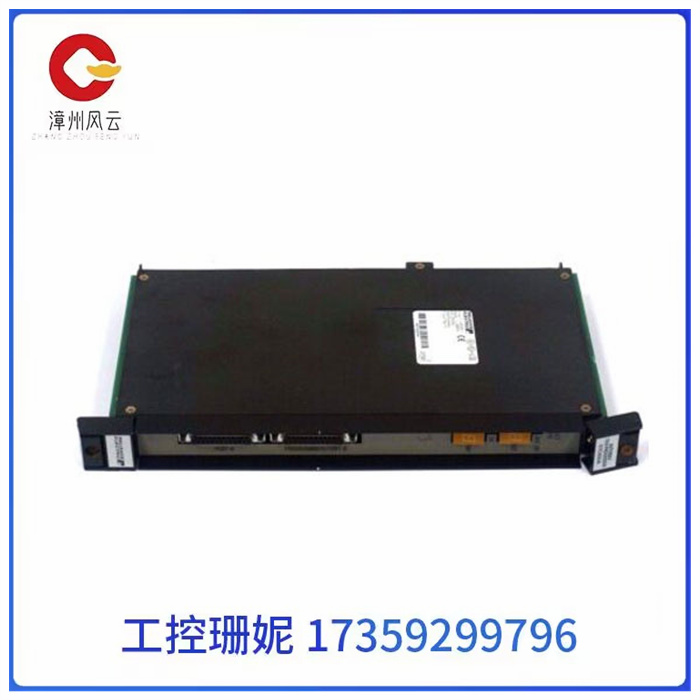

0-57435 模块

在可编程逻辑控制器系统设计时,首先应确定控制方案,下一步工作就是可编程逻辑控制器工程设计选型。工艺流程的特点和应用要求是设计选型的主要依据。可编程逻辑控制器及有关设备应是集成的、标准的,按照易于与工业控制系统形成一个整体,易于扩充其功能的原则选型所选用可编程逻辑控制器应是在相关工业领域有投运业绩、成熟可靠的系统,可编程逻辑控制器的系统硬件、软件配置及功能应与装置规模和控制要求相适应。

熟悉可编程序控制器、功能表图及有关的编程语言有利于缩短编程时间,因此,工程设计选型和估算时,应详细分析工艺过程的特点、控制要求,明确控制任务和范围确定所需的操作和动作,然后根据控制要求,估算输入输出点数、所需存储器容量、确定可编程逻辑控制器的功能、外部设备特性等,后选择有较高性能价格比的可编程逻辑控制器和设计相应的控制系统。[5]点数估算I/O点数估算时应考虑适当的余量,通常根据统计的输入输出点数,再增加10%~20%的可扩展余量后,作为输入输出点数估算数据。实际订货时,还需根据制造厂商可编程逻辑控制器的产品特点,对输入输出点数进行圆整。

存储器容量

存储器容量是可编程序控制器本身能提供的硬件存储单元大小,程序容量是存储器中用户应用项目使用的存储单元的大小,因此程序容量小于存储器容量。设计阶段,由于用户应用程序还未编制,因此,程序容量在设计阶段是未知的,需在程序调试之后才知道。为了设计选型时能对程序容量有一定估算,通常采用存储器容量的估算来替代。[5]存储器内存容量的估算没有固定的公式,许多文献资料中给出了不同公式,大体上都是按数字量I/O点数的10~15倍,加上模拟I/O点数的100倍,以此数为内存的总字数(16位为一个字),另外再按此数的25%考虑余量。[5]

0-57435 模块

In the design of programmable logic controller system, the control scheme should be determined first, and the next step is the selection of programmable logic controller engineering design. Process characteristics and application requirements are the main basis for design and selection. Programmable logic controller and related equipment should be integrated, standard, in accordance with the principle of easy to form a whole with the industrial control system, easy to expand its function selection of the selected programmable logic controller should be in the relevant industrial fields have operational performance, mature and reliable system, The system hardware, software configuration and function of the programmable logic controller should be adapted to the device scale and control requirements.

Familiar with programmable controller, function chart and related programming language is conducive to shortening programming time, therefore, in the selection and estimation of engineering design, the characteristics of the process and control requirements should be analyzed in detail, the control task and scope should be defined to determine the required operations and actions, and then according to the control requirements, Estimate the number of input and output points, the required memory capacity, determine the functions of the programmable logic controller, the characteristics of external devices, etc., and then select the programmable logic controller with higher performance and price ratio and design the corresponding control system. [5] I/O points estimation should consider the appropriate margin when estimating I/O points, usually according to the statistical input and output points, and then increase the expandable margin of 10% to 20%, as the input and output points estimation data. When actually ordering, it is also necessary to round out the input and output points according to the product characteristics of the manufacturer's programmable logic controller.

Memory capacity

The memory capacity is the size of the hardware storage unit that can be provided by the programmable controller itself, and the program capacity is the size of the storage unit used by the user application project in the memory, so the program capacity is less than the memory capacity. In the design phase, because the user application has not yet been written, the program capacity is unknown in the design phase and needs to be known after the program debugging. In order to have a certain estimation of program capacity during the design and selection, the estimation of memory capacity is usually used instead. [5] There is no fixed formula for the estimation of memory memory capacity, and different formulas are given in many literatures, which are generally 10 to 15 times the number of digital I/O points, plus 100 times the analog I/O points, which is the total number of words in memory (16 bits for a word), and then consider the margin according to 25% of this number. [5]

相关推荐