手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

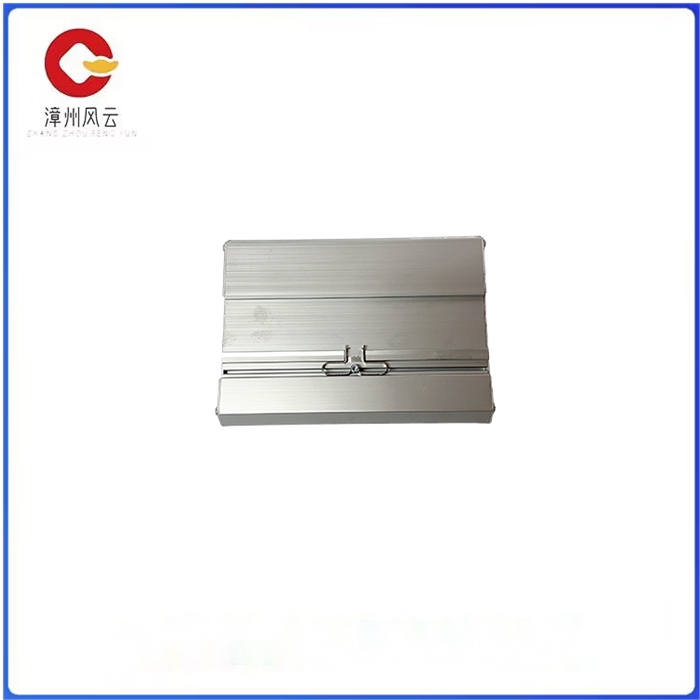

KSD211B耦合装置单元应用于工控行业控制器防护等级IP54零件号KSD211B高度20mm适配电机功率66KW适用管道6额定电流66mA适用场所电力行业通信

产品详情

若需替换一个模块,用户应确认被安装的模块是同类型。有些I/O系统允许带电更换模块,而有些则需切断电源。若替换后可解决问题,但在一相对较短时间后又发生故障,那么用户应检查能产生电压的感性负载,也许需要从外部抑制其电流尖峰。如果保险丝在更换后易被烧断,则有可能是模块的输出电流超限,或输出设备被短路。

PLC的故障诊断是一个十分重要的问题,是保证PLC控制系统正常、可靠运行的关键。本文对常用的故障诊断方法进行了探讨。在实际工作过程中,应充分考虑到对PLC的各种不利因素,定期进行检查和日常维护,以保证PLC控制系统安全、可靠地运行。笔者近几年在维护和修理PLC系统中,总结了一些快速查找PLC系统故障原因的经验,现与大家交流如下。

一个典型的PLC系统包括一个现场PLC站,和通过高速数据线与之相连的上位机以及模拟屏PLC站,上位机用以显示各种图形和数据,模拟屏PLC站用来驱动模拟屏上的发光二极管。整个PLC系统与外联设备相接,就构成了一个自动控制系统。

通常将PLC当作一个黑盒子,我们可以简单地根据I/O信号来判断故障的位置。判断故障的情况有两种,即模拟屏上闪烁的故障信号和该运行的设备在模拟屏上无显示。

1、模拟屏上闪烁的故障信号

根据PLC控制站图纸,先检查该设备在模拟屏PLC柜内的显示状态,如果相符合再检查现场PLC柜的显示状态,同样符合时再继续检查PLC柜的I/O端子、外联设备的I/O端子,并由此推断出是设备故障还是PLC故障。

If a module needs to be replaced, the user should confirm that the installed module is of the same type. Some I/O systems allow the module to be replaced while live, while others require the power to be disconnected. If the replacement resolves the problem, but the failure occurs after a relatively short period of time, the user should check the inductive load that produces voltage and may need to suppress its current spikes externally. If the fuse is easily blown after replacement, it may be that the output current of the module exceeds the limit, or the output device is short-circuited.

The fault diagnosis of PLC is a very important problem, which is the key to ensure the normal and reliable operation of PLC control system. In this paper, the common fault diagnosis methods are discussed. In the actual work process, should fully take into account the various adverse factors to the PLC, regular inspection and daily maintenance, to ensure that the PLC control system safe and reliable operation. In recent years, the author in the maintenance and repair of PLC system, summed up some quickly find the cause of PLC system failure experience, and now communicate with you as follows.

A typical PLC system includes a field PLC station, and the upper computer connected to it through a high-speed data line and the analog screen PLC station, the upper computer is used to display various graphics and data, and the analog screen PLC station is used to drive the light-emitting diode on the analog screen. The whole PLC system is connected with the external equipment to form an automatic control system.

The PLC is usually regarded as a black box, and we can simply determine the location of the fault according to the I/O signal. There are two ways to determine the fault, that is, the fault signal blinking on the analog screen and the running device is not displayed on the analog screen.

1, the analog screen blinking fault signal

According to the PLC control station drawings, first check the display status of the device in the PLC cabinet on the analog screen, and then check the display status of the on-site PLC cabinet if it is consistent with the same, and then continue to check the I/O terminal of the PLC cabinet and the I/O terminal of the external equipment, and deduce whether the equipment is faulty or the PLC is faulty.

相关推荐