手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

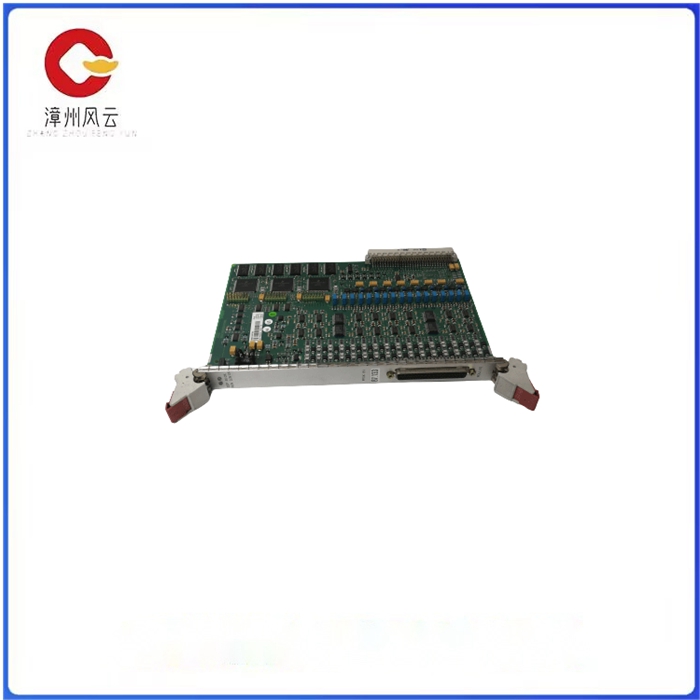

PFSK1513BSE018876R1励磁通讯控制器包括以下几个方面:外观检查:定期检查控制器的外观,包括外壳和内部部件,以确保其没有损坏或异常情况。电源和电缆

产品详情

包括以下几个方面:

外观检查:定期检查控制器的外观,包括外壳和内部部件,以确保其没有损坏或异常情况。

电源和电缆检查:检查控制器的电源和电缆连接是否良好,没有松动或损坏。确保电源线没有老化或损坏,如有需要,及时更换。

运行状态记录:定期记录控制器的运行状态,包括输出信号、报警状态等,以监测其工作状态。

软件更新:根据制造商的建议,定期更新控制器的软件,以提高其性能和功能。

清洁:定期清洁控制器的外壳和内部部件,以保持其良好的运行状态。使用干净的布和温和的清洁剂进行清洁,避免使用强烈的化学清洁剂。

检查电源和电缆:确保控制器的电源和电缆连接良好,没有松动或损坏。检查电源线是否老化或损坏,如有需要,及时更换。

检查传感器和执行器:检查传感器和执行器是否正常工作,如有问题,及时进行更换或调整。

定期校准:按照制造商的建议,定期对控制器进行校准,以确保其准确性和可靠性。

维护日志:记录控制器的维护记录,包括维护时间、维护内容等,以便及时发现和解决问题。

ABB PFSK151 3BSE018876R1 励磁通讯控制器是一款高性能、功能强大的工业控制器,具有以下特征:

高速处理能力:该控制器采用高性能的处理器和大容量内存,可以快速地处理各种复杂的控制算法和数据交换任务,提高系统的响应速度和效率。

多种通信接口:该控制器通常配备了多种通信接口,如以太网、串行通信等接口,可以满足不同用户的需求,实现与其它设备或系统的通信和数据交换。

可编程性:该控制器支持多种编程语言,如C/C++、Ladder Logic等,使用户可以根据自己的需要编写自定义的控制程序。

对于ABB PFSK151 3BSE018876R1 励磁通讯控制器的维修,可以参考以下步骤:

电源检查:检查控制器的电源是否正常,包括电压、电流等参数是否在规定范围内。

外观检查:检查控制器的外观是否有损坏或异常现象。如有问题,需要及时进行更换或修复。

接线检查:检查控制器与外部设备的接线是否牢固,是否有松动或损坏的情况。如果发现接线问题,需要重新连接或更换接线。

软件更新:根据制造商的推荐,定期更新控制器的软件,以保持其功能和性能的稳定性和可靠性。

数据备份:在维修过程中,建议对控制器内的数据进行备份,以防止数据丢失。

故障诊断:如果控制器出现故障或异常情况,需要进行详细的检查和诊断。可以查阅相关的故障诊断手册或联系专业的维修人员或制造商的技术支持团队进行咨询和指导。

部件更换:如果需要更换部件或升级软件,需要根据制造商的推荐进行操作。在更换部件时,需要注意使用正确的部件和遵循正确的更换步骤。

存储与保管:在长时间不使用控制器时,应将其存放在干燥、通风的地方,避免阳光直射和潮湿环境。同时,定期检查控制器的绝缘性能,确保其安全可靠。

需要注意的是,具体的维修步骤和操作方法需要根据控制器的具体型号和规格以及制造商的推荐进行操作。因此,在进行维修前,建议先查阅相关的维修手册或联系专业的维修人员或制造商的技术支持团队进行咨询和指导。

Include the following aspects:

Appearance inspection: Check the appearance of the controller regularly, including the housing and internal components, to ensure that there is no damage or abnormal conditions.

Power and cable check: Check that the power and cable connections of the controller are good and not loose or damaged. Ensure that the power cable is not aged or damaged, and replace it in time if necessary.

Operation status record: regularly record the operation status of the controller, including output signal, alarm status, etc., to monitor its working status.

Software updates: The controller's software is regularly updated to improve its performance and functionality, as recommended by the manufacturer.

Cleaning: Regularly clean the enclosure and internal components of the controller to keep it in good working condition. Use a clean cloth and a mild cleaner for cleaning, and avoid strong chemical cleaners.

Check the power supply and cables: Ensure that the power supply and cables of the controller are properly connected and not loose or damaged. Check whether the power cable is aged or damaged, and replace it if necessary.

Check the sensor and actuator: check whether the sensor and actuator are working properly. If there is a problem, replace or adjust it in time.

Periodic calibration: The controller is calibrated regularly as recommended by the manufacturer to ensure its accuracy and reliability.

Maintenance logs: Record maintenance records of the controller, including the maintenance time and content, to discover and rectify faults in a timely manner.

The ABB PFSK151 3BSE018876R1 Excitation Communication controller is a high performance and powerful industrial controller with the following characteristics:

High-speed processing capability: The controller adopts high-performance processor and large memory, which can quickly process various complex control algorithms and data exchange tasks, and improve the response speed and efficiency of the system.

A variety of communication interfaces: The controller is usually equipped with a variety of communication interfaces, such as Ethernet, serial communication and other interfaces, which can meet the needs of different users and realize communication and data exchange with other devices or systems.

Programmability: The controller supports a variety of programming languages, such as C/C++, Ladder Logic, etc., allowing users to write custom control programs according to their needs.

For the maintenance of ABB PFSK151 3BSE018876R1 excitation communication controller, please refer to the following steps:

Power check: Check whether the power supply of the controller is normal, including voltage, current and other parameters are within the specified range.

Appearance check: Check whether the appearance of the controller is damaged or abnormal. If there is a problem, it needs to be replaced or repaired in time.

Cable connection check: Check whether the cable between the controller and external devices is firm, loose or damaged. If cables are faulty, reconnect or replace the cables.

Software update: According to the manufacturer's recommendation, the controller's software is updated regularly to maintain the stability and reliability of its function and performance.

Data backup: During maintenance, you are advised to back up data on the controller to prevent data loss.

Fault diagnosis: If the controller is faulty or abnormal, you need to perform detailed check and diagnosis. You can consult the relevant troubleshooting manual or contact professional maintenance personnel or the manufacturer's technical support team for advice and guidance.

Parts replacement: If you need to replace parts or upgrade software, follow the manufacturer's recommendations. When replacing parts, it is necessary to take care to use the correct parts and follow the correct replacement procedures.

Storage and storage: When the controller is not used for a long time, it should be stored in a dry and ventilated place, away from direct sunlight and humid environment. At the same time, check the insulation performance of the controller regularly to ensure its safety and reliability.

It should be noted that the specific repair steps and operation methods need to be operated according to the specific model and specification of the controller and the manufacturer's recommendation. Therefore, before performing maintenance, it is recommended to consult the relevant maintenance manual or contact professional maintenance personnel or the manufacturer's technical support team for consultation and guidance.

相关推荐