手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

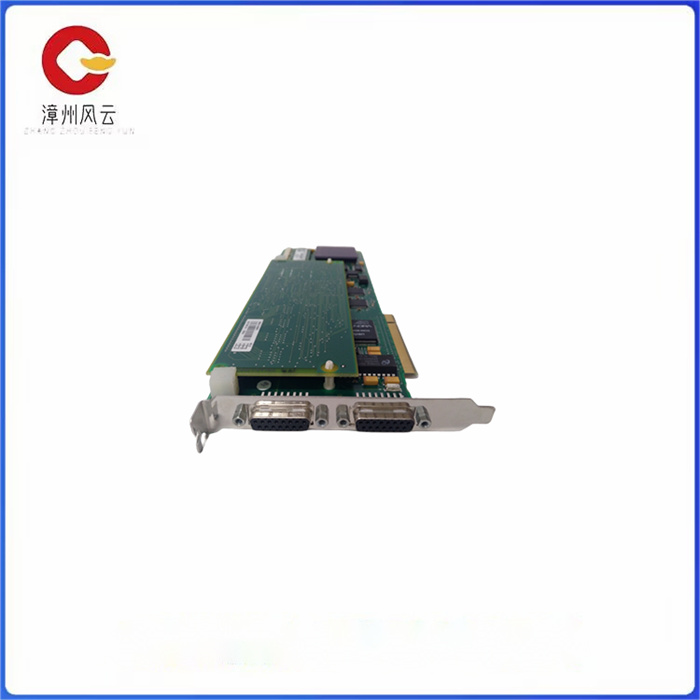

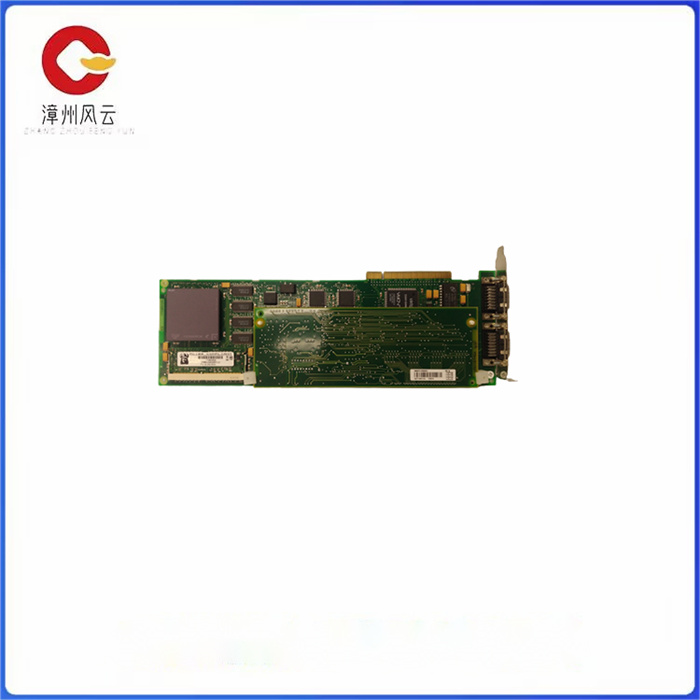

PU5163BSE013064R1ABB用于监控和控制工业过程品牌ABB是否支持加工定制是物料编码PU516系统功能强大系统环境正常系统能力自动颜色白色I/O点

产品详情

ABB的PU516 3BSE013064R1是一个功能强大的可编程逻辑控制器(PLC),用于监控和控制工业过程。以下是关于该PLC的一些关键特点和功能:

可编程逻辑控制:PU516 3BSE013064R1具有强大的编程功能,允许用户根据特定的工业过程需求进行定制。通过使用PLC编程语言(如Ladder Logic、Structured Text或Function Block Diagrams),用户可以创建复杂的控制逻辑,从而精确地监控和自动化工业设备。

工业过程监控:PU516 3BSE013064R1配备多种输入/输出(I/O)模块,这些模块可以连接到各种传感器和执行器,从而实时监控工业过程的参数(如温度、压力、流量等)。通过读取这些参数,PLC可以确保生产过程在预设的参数范围内运行,并在必要时触发警报或自动调整设备。

控制功能:除了监控,PU516 3BSE013064R1还能执行各种控制操作。例如,它可以自动调整机器的速度、流量或温度,以保持生产过程的稳定。通过使用控制算法(如比例-积分-微分控制),PLC能够精确地调节过程参数,从而提高产品质量并降低能耗。

通讯能力:PU516 3BSE013064R1具有多种通讯接口,如以太网、串行端口等,使其能够与其它设备或系统进行数据交换。这使得PU516能够与其它PLC、HMI(人机界面)设备或上位机软件进行通信,从而实现更广泛的监控和控制功能。

可靠性与安全性:PU516 3BSE013064R1设计用于恶劣的工业环境,具有很高的可靠性和安全性。它通常具有故障检测和恢复功能,能够在出现故障时自动切换到备用设备或降级运行模式,从而最大限度地减少停机时间。

易于集成与维护:PU516 3BSE013064R1具有标准化的编程接口和通讯协议,这使得它易于集成到现有的工业控制系统中。此外,该PLC通常配备有诊断工具和强大的编程软件,使得维护和故障排除更加方便。

扩展性:PU516 3BSE013064R1设计灵活,可根据需要进行扩展。通过添加更多的I/O模块或扩展模块,用户可以增加监控和控制点数,以满足不断增长的生产需求。

支持多种行业应用:由于其强大的功能和灵活性,PU516 3BSE013064R1适用于各种工业领域,如制造业、化工、食品加工和制药等。通过定制控制逻辑和用户界面,该PLC能够满足特定行业的特定需求。

总之,ABB的PU516 3BSE013064R1 PLC是一个功能全面、可靠性高的控制解决方案,适用于各种工业过程的监控和控制需求。通过仔细规划和配置,它可以极大地提高生产效率、产品质量和设备可靠性。

ABB's PU516 3BSE013064R1 is a powerful programmable logic controller (PLC) for monitoring and controlling industrial processes. Here are some of the key features and functions of the PLC:

Programmable logic control: The PU516 3BSE013064R1 has powerful programming capabilities that allow users to customize to specific industrial process needs. By using PLC programming languages such as Ladder Logic, Structured Text, or Function Block Diagrams, users can create complex control logic to precisely monitor and automate industrial equipment.

Industrial process monitoring: The PU516 3BSE013064R1 is equipped with a variety of input/output (I/O) modules that can be connected to various sensors and actuators to monitor parameters of industrial processes (such as temperature, pressure, flow, etc.) in real time. By reading these parameters, the PLC can ensure that the production process is operating within preset parameters and trigger alarms or automatically adjust equipment if necessary.

Control function: In addition to monitoring, the PU516 3BSE013064R1 can also perform various control operations. For example, it can automatically adjust the speed, flow rate or temperature of the machine to keep the production process stable. By using control algorithms such as proportional-integral-differential control, PLCS are able to precisely adjust process parameters, thereby improving product quality and reducing energy consumption.

Communication capability: PU516 3BSE013064R1 has a variety of communication interfaces, such as Ethernet, serial ports, etc., so that it can exchange data with other devices or systems. This enables the PU516 to communicate with other PLC, HMI (Human machine interface) devices, or upper computer software for a wider range of monitoring and control functions.

Reliability and safety: The PU516 3BSE013064R1 is designed for use in harsh industrial environments with high reliability and safety. It typically has a fault detection and recovery feature that automatically switches to standby equipment or degraded operating mode in the event of a failure, thereby minimizing downtime.

Easy integration and maintenance: The PU516 3BSE013064R1 has a standardized programming interface and communication protocol, which makes it easy to integrate into existing industrial control systems. In addition, the PLC is usually equipped with diagnostic tools and powerful programming software, making maintenance and troubleshooting more convenient.

Scalability: The PU516 3BSE013064R1 is designed to be flexible and can be expanded as needed. By adding more I/O modules or expansion modules, users can increase the number of monitoring and control points to meet growing production demands.

Support for a wide range of industry applications: Due to its powerful functionality and flexibility, the PU516 3BSE013064R1 is suitable for a variety of industrial areas, such as manufacturing, chemicals, food processing and pharmaceuticals. By customizing the control logic and user interface, the PLC is able to meet the specific needs of specific industries.

In short, ABB's PU516 3BSE013064R1 PLC is a full-featured, highly reliable control solution for a wide range of industrial process monitoring and control needs. With careful planning and configuration, it can greatly improve production efficiency, product quality and equipment reliability.

相关推荐