手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

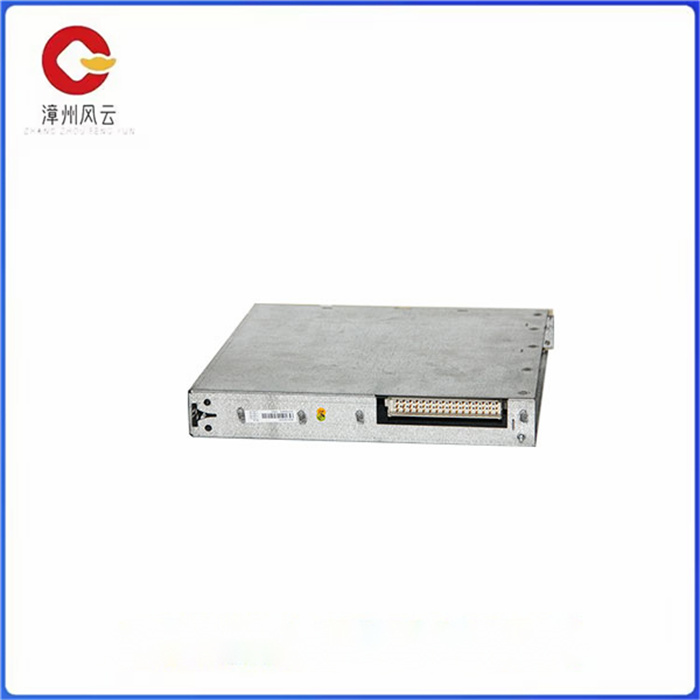

ABBPM633可编程逻辑控制器中央控制系统品牌ABB输出频率624Hz特点全新系统功能控制和自动化任务系统环境稳定系统能力提供高速处理和通信能力颜色以实物为准

产品详情

产品介绍

产品型号名称:PM633模拟量输入模块

2.1 控制过程

系统将移动距离、速度、加速度写入控制卡,控制卡通过计算输出一定数目和频率的脉冲传送到驱动器上,由驱动器控制电机移动,电机带动丝杠连接的平台移动。移动过程中,连接在平台上的物体拉伸产生拉压力,经拉力传感器传输到控制卡,软件或触摸屏读取数据并显示。软件显示时间与拉力曲线,并且通过串口读取电机电流计算拉压力曲线显示。

2.2 试验过程

样品一端(或其他方式固定)在板上,板两端通过连接件和工装件连接。样品另一端通过夹具和球形轴承连接。

静态试验中:样品一端固定,另一端用一定的力(小于2500N)去顶,使固定的一端断裂,控制器通过压力传感器反馈到样品断裂时候的扭矩,上位机软件可实时显示受力曲线,保存数据。

动态测试中:触摸屏或电脑可以设定并记录振动的次数,振动振幅可调,分±5mm, ±8mm, ±10mm, ±20mm, ±30mm,精度按1mm设定。频率1Hz,依照现场情况,调节频率档位。上位机软件根据监测的电流计算受力曲线并保存数据。

3 PM633 系统介绍

3.1 主要功能

(1) 实时显示焊接测试的拉压力-时间曲线。

(2) 实时检测机器故障,显示当前位置,震动次数等参数。

(3) 打开,保存曲线文件为txt格式。

(4) 可进行连动与寸动控制,进行静态测试,动态测试。

(5) 运动到次数或超过拉力值后,自动停止,弹出提示信息,保存文件。

(6) 触摸屏也具有显示参数及控制功能,可与计算机软件同步控制。

Product introduction

Model name: PM633 analog input module

2.1 Control process

The system writes the moving distance, speed and acceleration into the control card, and the control card transmits to the driver by calculating and output a certain number and frequency of pulses. The driver controls the motor movement, and the motor drives the platform connected with the lead screw to move. During the movement, the object connected to the platform is stretched to generate tension, which is transmitted by the tension sensor to the control card, software or touch screen to read the data and display. The software displays the time and tension curve, and reads the motor current through the serial port to calculate the tension curve display.

2.2 Test process

One end of the sample is (or is otherwise fixed) on a plate, and the two ends of the plate are connected by connecting pieces and tooling pieces. The other end of the sample is connected by a clamp and a spherical bearing.

In static test: one end of the sample is fixed, and the other end is topped with a certain force (less than 2500N), so that the fixed end is broken. The controller feedbacks the torque of the sample at the time of breaking through the pressure sensor, and the upper computer software can display the force curve in real time and save data.

In dynamic test: touch screen or computer can set and record the number of vibration, vibration amplitude is adjustable, ±5mm, ±8mm, ±10mm, ±20mm, ±30mm, accuracy is set by 1mm. Frequency 1Hz, according to the site situation, adjust the frequency gear. The upper computer software calculates the stress curve according to the monitored current and saves the data.

3 PM633 System Overview

3.1 Main Functions

(1) Real-time display of tensile pressure-time curve of welding test.

(2) Real-time detection of machine faults, display the current position, vibration times and other parameters.

(3) Open and save the curve file in txt format.

(4) Can be connected and inching control, static test, dynamic test.

(5) After the movement to the number of times or exceeds the tension value, it will automatically stop, pop up a prompt message, and save the file.

(6) The touch screen also has display parameters and control functions, which can be controlled synchronously with computer software.

相关推荐