手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

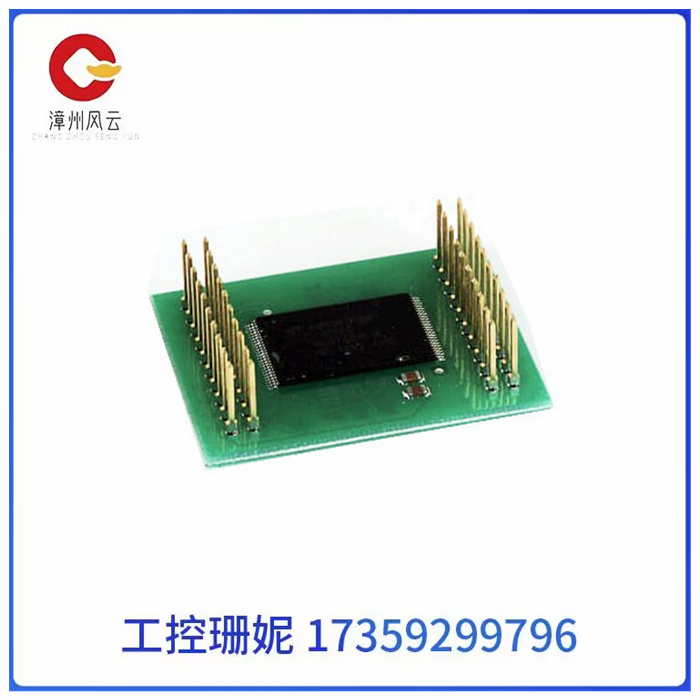

ABB HIEE401807R0001轧机驱动系统通信控制器品牌ABB产品特性模块是否进口否产地瑞士加工定制否工作电压220V输出频率30kHz产品认证合格系列8652542物料编码HIEE401807R0001可售卖地全国型号HIEE401807R0001ABB HIEE401807R0001轧机驱动系统通信控制器ABB AC 500-S PLC的安全PLC模块添加到机器控制系统中,通过使用PR

产品详情

ABB HIEE401807R0001轧机驱动系统通信控制器

ABB HIEE401807R0001轧机驱动系统通信控制器

ABB AC 500-S PLC的安全PLC模块添加到机器控制系统中,通过使用PROFINET上的PROFIsafe协议的网络架构来增强20米长轧机的安全性,以提供对六个独立安全区域的独立控制。

分区布置意味着,当操作员安全进入其他区域时,机器的某些部分仍可运行,在其他区域,通过切断电源来确保安全。大约50个安全PLC I/O通道用于连接闸门开关、光幕保护和紧急停止按钮。

I/O还监控压力开关,以检测液压动力是否被禁用,以便进行维护,并控制电机驱动的电源。安全速度控制是新PLC提供的安全控制的另一个方面-确保手或手指不会夹在轧机的皮带和辊子之间。山特维克选择ABB的AC500-S安全PLC用于这种应用,是因为在该机器和其他机械控制项目上,标准非安全AC500 PLC架构具有良好的经验。

AC500-S安全PLC还为山特维克提供了使用浮点数的可能性,这简化了该项目计算速度等任务所需的安全编程。事实上,ABB PLC的标准版本已经在轧机上使用,大大简化了安全升级这是因为安全PLC硬件与标准AC500 PLCs具有相同的外观和感觉,允许在同一系统中混合使用安全和非安全功能。

ABB HIEE401807R0001轧机驱动系统通信控制器

The Safety PLC module of ABB AC 500-S PLC is added to the machine control system to enhance the safety of the 20-meter long rolling mill by using the network architecture of the PROFIsafe protocol on PROFINET to provide independent control over six independent safety zones.

The zoned arrangement means that some parts of the machine can still operate while the operator is safely in other areas, where the power is cut off to ensure safety. Approximately 50 secure PLC I/O channels are used to connect gate switches, light curtain protection and emergency stop buttons.

I/O also monitors pressure switches to detect if hydraulic power is disabled for maintenance and to control the power supply to the motor drive. Safe speed control is another aspect of the safety control offered by the new PLC - ensuring that hands or fingers do not get caught between the mill's belt and the roll. Sandvik chose ABB's AC500-S safety PLC for this application because of its proven experience with the standard non-safety AC500 PLC architecture for this and other mechanical control projects.

The AC500-S safety PLC also gives Sandvik the possibility to use floating-point numbers, which simplifies the safe programming required for tasks such as computational speed for the project. In fact, a standard version of ABB PLC is already in use on rolling mills, greatly simplifying safety upgrades. This is because the safety PLC hardware has the same look and feel as the standard AC500 PLCs, allowing for a mix of safety and non-safety functions in the same system.

相关推荐