手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

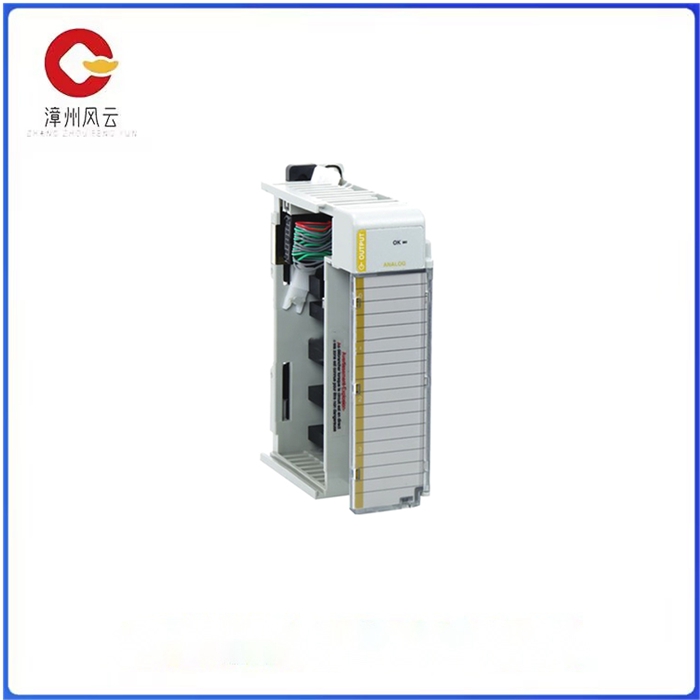

1769-OF4CI伺服驱动冗余模块电机品牌AllenBradley(罗克韦尔)加工定制否电压24V控制方式电流矢量输出频率50KHz滤波器内置1A滤波器功耗3

产品详情

1769-OF4CI 是罗克韦尔自动化(Rockwell Automation)的一种伺服驱动冗余模块,专为电机控制而设计。这种模块的主要目的是提供高度的可靠性和冗余性,以确保在工业自动化应用中,即使主伺服驱动器出现故障,也能通过备份或冗余驱动器继续控制电机,从而保持生产线的连续运行。

以下是关于 1769-OF4CI 伺服驱动冗余模块的一些详细信息:

冗余功能:该模块的核心特点是其冗余能力。它配备了两个或多个伺服驱动器,当主驱动器出现故障时,备份驱动器会立即接管控制,确保电机继续正常运行。这种冗余设计显著提高了系统的可靠性和稳定性。

电机控制:1769-OF4CI 模块主要用于控制伺服电机,这些电机广泛应用于需要高精度、快速响应和高效能的运动控制应用中。通过精确的电机控制,该模块可以实现复杂的运动轨迹、速度和位置控制。

集成和通信:1769-OF4CI 模块通常与罗克韦尔自动化的 ControlLogix 或 CompactLogix 控制器配合使用,通过高速的通信协议(如 EtherNet/IP)与控制器进行通信,实现实时数据交换和控制指令的传输。

配置和监控:用户可以通过罗克韦尔自动化的编程软件(如 Studio 5000)对 1769-OF4CI 模块进行配置、监控和故障诊断。这些软件提供了丰富的功能和工具,使用户能够轻松地设置参数、监控运行状态、诊断故障并进行必要的调整。

广泛的应用领域:由于其高可靠性、精确控制和冗余功能**,1769-OF4CI** 伺服驱动冗余模块广泛应用于各种工业自动化领域,如包装机械、食品加工、物料搬运、机床等。

需要注意的是,具体的模块功能、规格和参数可能会因产品升级或更新而有所变化。因此,在选择和使用 1769-OF4CI 伺服驱动冗余模块时,建议参考罗克韦尔自动化的官方文档或联系相关技术支持人员,以获取最准确和详细的信息。此外,根据实际应用需求,用户还需要考虑电机的类型、规格和性能等因素来选择合适的伺服驱动冗余模块。

The 1769-OF4CI is a servo-driven redundant module from Rockwell Automation designed for motor control. The main purpose of this module is to provide a high degree of reliability and redundancy to ensure that in industrial automation applications, even if the main servo drive fails, the motor can continue to be controlled through backup or redundant drives, thus maintaining the continuous operation of the production line.

Here are some details about the 1769-OF4CI servo Drive redundancy module:

Redundancy function: The core feature of this module is its redundancy capability. It is equipped with two or more servo drives, and when the main drive fails, the backup drive immediately takes over control, ensuring that the motor continues to operate normally. This redundant design significantly improves the reliability and stability of the system.

Motor control: The 1769-OF4CI module is mainly used to control servo motors, which are widely used in motion control applications requiring high precision, fast response and high performance. Through precise motor control, the module can achieve complex motion trajectory, speed and position control.

Integration and communication: The 1769-OF4CI module is typically used in conjunction with Rockwell Automation's ControlLogix or CompactLogix controllers to communicate with the controller via high-speed communication protocols (such as EtherNet/IP) for real-time data exchange and transmission of control instructions.

Configuration and monitoring: Users can configure, monitor, and troubleshoot the 1769-OF4CI module with Rockwell Automation programming software such as Studio 5000. These software offers a wealth of features and tools that make it easy for users to set parameters, monitor health, diagnose faults, and make necessary adjustments.

Wide range of applications: Due to its high reliability, precise control and redundancy functions, the 1769-OF4CI** servo drive redundancy module is widely used in various industrial automation fields, such as packaging machinery, food processing, material handling, machine tools, etc.

It should be noted that specific module functions, specifications and parameters may change due to product upgrades or updates. Therefore, when selecting and using the 1769-OF4CI servo drive redundancy module, it is recommended to refer to the official documentation of Rockwell Automation or contact the relevant technical support personnel for the most accurate and detailed information. In addition, according to the actual application needs, users also need to consider the type of motor, specifications and performance and other factors to select the appropriate servo drive redundancy module.

相关推荐