手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

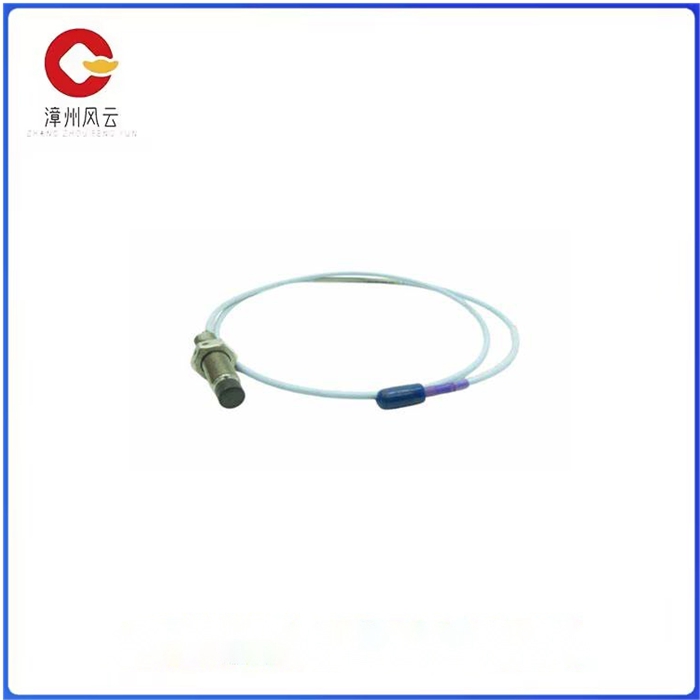

330703-00-09-10-02-cn机械保护系统品牌本特利传感器类型电涡流传感器输出类型电压安装类型螺纹工作温度25℃系列bently3300XLNsv最

产品详情

330703-00-09-10-02-cn 机械保护系统是一种用于监测和保护机械设备运行状态的先进系统。该系统结合了多种传感器和信号处理技术,能够实时检测机械设备的振动、位移、温度等关键参数,并通过算法分析这些数据,以判断机械设备的运行状态是否存在异常。

具体来说,330703-00-09-10-02-cn 机械保护系统通常包括以下几个主要组成部分:

传感器:这些传感器被安装在机械设备的关键部位,用于实时测量各种物理量,如振动、位移、温度等。传感器将测量到的信号转换为电信号,以便后续处理和分析。

信号处理器:信号处理器接收来自传感器的电信号,进行滤波、放大、数字化等处理,以提取出有用的信息。

分析软件:软件对处理后的数据进行进一步的分析,通过比较预设的阈值或模式识别算法,判断机械设备是否处于正常状态。

报警与控制系统:一旦检测到异常情况,系统会触发报警机制,通知操作人员或自动采取保护措施,如停机、调整运行参数等,以避免设备损坏或生产事故。

330703-00-09-10-02-cn 机械保护系统具有以下优点:

实时监测:能够连续不断地监测机械设备的运行状态,及时发现潜在问题。

高精度测量:采用先进的传感器和信号处理技术,实现高精度的参数测量和分析。

智能诊断:通过算法和数据分析,能够自动判断机械设备的运行状态,提供智能化的诊断建议。

易于集成:系统可以与现有的工业自动化系统无缝集成,提高整体运行效率。

该系统广泛应用于各种工业领域,如石油化工、电力、冶金、矿山等,为机械设备的安全运行提供了有力保障。同时,通过优化设备运行和维护策略,该系统也有助于提高生产效率、降低运营成本。

330703-00-09-10-02-cn Mechanical Protection system is an advanced system for monitoring and protecting the operating status of mechanical equipment. The system combines a variety of sensors and signal processing technologies to detect key parameters such as vibration, displacement and temperature of mechanical equipment in real time, and analyze these data through algorithms to determine whether there is an anomaly in the running state of mechanical equipment.

Specifically, a 330703-00-09-10-02-cn mechanical protection system typically includes the following main components:

Sensors: These sensors are installed in key parts of the mechanical equipment to measure various physical quantities in real time, such as vibration, displacement, temperature, etc. The sensor converts the measured signal into an electrical signal for subsequent processing and analysis.

Signal processor: The signal processor receives the electrical signal from the sensor, filters, amplifies, digitizes, etc., to extract useful information.

Analysis software: The software performs further analysis of the processed data to determine whether the mechanical equipment is in normal condition by comparing the preset threshold or pattern recognition algorithm.

Alarm and control system: Once an abnormal situation is detected, the system will trigger an alarm mechanism to notify the operator or automatically take protective measures, such as shutdown, adjustment of operating parameters, etc., to avoid equipment damage or production accidents.

330703-00-09-10-02-cn Mechanical protection system has the following advantages:

Real-time monitoring: It can continuously monitor the operating status of mechanical equipment and find potential problems in time.

High-precision measurement: Advanced sensor and signal processing technology is used to achieve high-precision parameter measurement and analysis.

Intelligent diagnosis: Through algorithms and data analysis, it can automatically determine the running status of mechanical equipment and provide intelligent diagnosis suggestions.

Easy integration: The system can be seamlessly integrated with existing industrial automation systems to improve overall operational efficiency.

The system is widely used in various industrial fields, such as petrochemical, electric power, metallurgy, mining, etc., which provides a strong guarantee for the safe operation of machinery and equipment. At the same time, by optimizing equipment operation and maintenance strategies, the system also helps to improve production efficiency and reduce operating costs.

相关推荐