手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

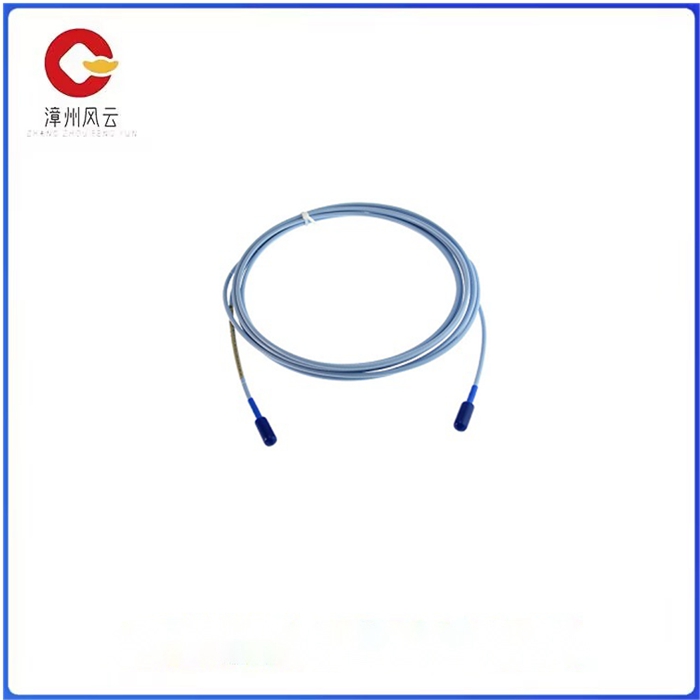

330130-085-00-05压缩机安全监视系统振动探头延长电缆品牌本特利/bently传感器类型电涡流传感器输出类型电压安装类型镀金铜接头对接工作温度25℃

产品详情

330130-085-00-05 压缩机安全监视系统振动探头延长电缆是专为压缩机安全监视系统设计的振动探头延长电缆。这种电缆的主要作用是扩展振动探头与监视系统之间的连接距离,使得在压缩机运行的过程中,即使振动探头安装位置较远,也能够稳定、准确地传输振动数据,从而实现对压缩机运行状态的实时监视和安全控制。

该延长电缆通常具备以下特性:

高抗干扰性:能够抵御环境中的电磁干扰,确保振动数据的稳定传输,避免因干扰导致的误报或漏报。

良好的柔韧性和耐磨性:电缆材质柔韧且耐磨,能够适应各种复杂的安装环境和弯曲需求,同时抵抗机械损伤,确保长期稳定运行。

耐高温和耐腐蚀:针对压缩机运行时可能产生的高温和腐蚀性环境,该电缆能够保持性能稳定,不易老化或损坏。

标准化接口:与振动探头和监视系统之间的接口兼容,方便快速安装和拆卸,降低维护成本。

在使用330130-085-00-05 压缩机安全监视系统振动探头延长电缆时,应确保电缆的正确连接和固定,避免在运行过程中受到过大的拉力或扭曲。同时,定期检查电缆的状态,如发现破损或老化现象,应及时更换,以确保压缩机安全监视系统的正常运行。

330130-085-00-05 Compressor safety monitoring system Vibration probe extension cable is designed for compressor safety monitoring system vibration probe extension cable. The main function of this cable is to extend the connection distance between the vibration probe and the monitoring system, so that during the operation of the compressor, even if the vibration probe is installed far away, the vibration data can be transmitted stably and accurately, so as to realize the real-time monitoring and safety control of the compressor operating state.

The extension cable usually has the following characteristics:

High anti-interference: It can resist electromagnetic interference in the environment, ensure the stable transmission of vibration data, and avoid false positives or missed positives caused by interference.

Good flexibility and wear resistance: The cable material is flexible and wear-resistant, which can adapt to a variety of complex installation environments and bending needs, while resisting mechanical damage to ensure long-term stable operation.

High temperature and corrosion resistance: Against the high temperature and corrosive environment that may occur during compressor operation, the cable can maintain stable performance and is not susceptible to aging or damage.

Standardized interface: Compatible with the interface between the vibration probe and the monitoring system, easy installation and removal, reducing maintenance costs.

When using the vibration probe of the 330130-085-00-05 compressor safety monitoring system to extend the cable, it should be ensured that the cable is correctly connected and fixed to avoid excessive tension or distortion during operation. At the same time, regularly check the status of the cable, if found damaged or aging phenomenon, should be replaced in time to ensure the normal operation of the compressor safety monitoring system.

相关推荐