手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

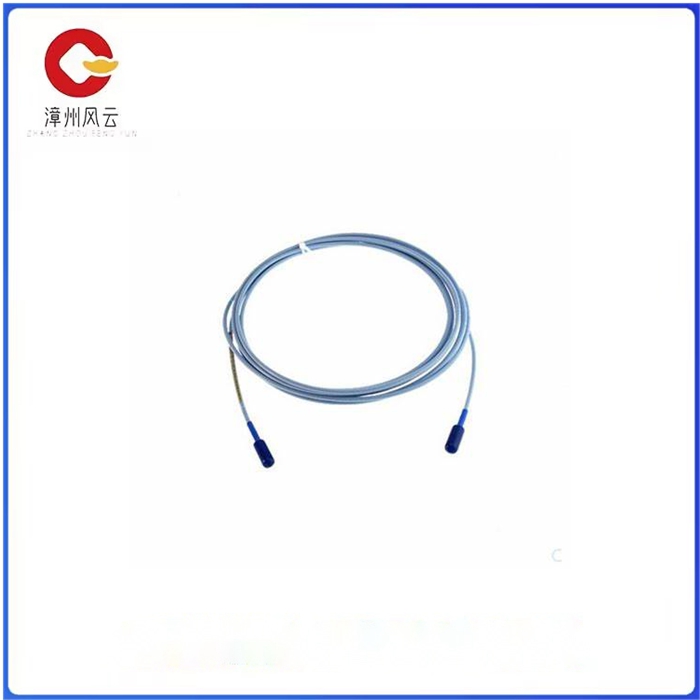

330130-040-00-CN延伸电缆4米涡轮机械控制品牌本特利bently最小包装量1规格20.4x22.2x3.7cm功能测量监测特点安装便捷名称延伸电缆

产品详情

330130-040-00-CN 延伸电缆4米是专为涡轮机械控制设计的电缆,用于将传感器或执行器与控制系统连接,实现信号传输或电源供应。这种电缆通常具有优异的电气性能、机械性能和环境适应性,以确保在涡轮机械控制系统中稳定可靠地运行。

涡轮机械控制系统通常涉及高速旋转的部件和复杂的工作环境,因此延伸电缆需要具备以下特点:

良好的电气性能:能够稳定传输信号,确保控制系统准确接收传感器数据或向执行器发送指令。

优秀的机械性能:能够抵御振动、冲击和扭曲等机械应力,保持电缆结构的完整性。

出色的环境适应性:能够耐高温、耐腐蚀,并在恶劣环境中长期稳定运行。

此外,该电缆的长度为4米,这个长度是根据涡轮机械控制系统的具体需求而设计的,既满足了连接需求,又方便了安装和维护。

在安装和使用这种延伸电缆时,应遵循相关的安装指南和安全规范,确保电缆正确连接、固定和保护,避免损坏或影响性能。同时,定期检查电缆的状态,及时更换损坏或老化的电缆,以确保涡轮机械控制系统的正常运行。

The 330130-040-00-CN Extension cable 4 m is a cable designed specifically for turbomachinery control to connect sensors or actuators to the control system for signal transmission or power supply. Such cables typically have excellent electrical properties, mechanical properties and environmental adaptability to ensure stable and reliable operation in turbomachinery control systems.

Turbomachinery control systems often involve high-speed rotating components and complex working environments, so extended cables need to have the following characteristics:

Good electrical performance: stable transmission of signals to ensure that the control system accurately receives sensor data or sends instructions to the actuator.

Excellent mechanical properties: It can resist mechanical stress such as vibration, shock and distortion to maintain the integrity of the cable structure.

Excellent environmental adaptability: high temperature resistance, corrosion resistance, and long-term stable operation in harsh environments.

In addition, the length of the cable is 4 meters, which is designed according to the specific requirements of the turbomachinery control system, both to meet the connection needs, and to facilitate installation and maintenance.

When installing and using this extension cable, follow the relevant installation guidelines and safety regulations to ensure that the cable is properly connected, secured, and protected to avoid damage or impact on performance. At the same time, check the status of cables regularly and replace damaged or aging cables in time to ensure the normal operation of the turbomachinery control system.

相关推荐