手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

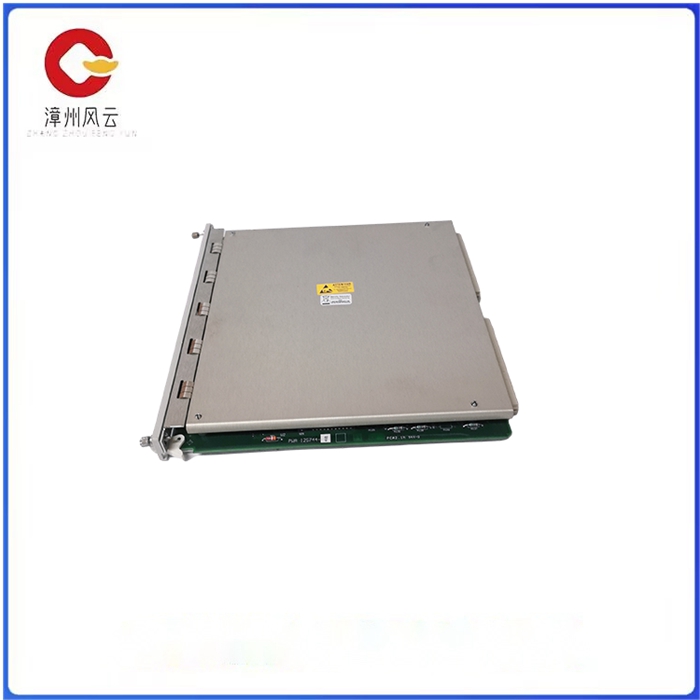

3500/42M140734-02本特利TSI系统数据接口模块品牌Bently产品特性模块是否进口否产地瑞士加工定制否工作电压230V输出频率50kHz产品认证

产品详情

产品特点

3500 系列 保护和状态监测系统是一个灵活、可扩展的平台,用于连续在线监测 关键的机器以及全厂流程中使用的所有其他机器资产,所有这些都在一个综合系统中提供。

可靠合规

兼容且灵活

与系统 1 通信

可用选项

安全认证

3500机械保护系统显示器

带有彩色触摸屏和 I/O 模块的3500 /94M VGA 触摸屏显示 模块可在机器或控制室显示重要的 3500 数据。VGA 具有 3500 个振动级别、系统和警报事件列表以及模块、通道和警报数据以及九个自定义显示选项。用于 Direct、1X、Gap 和警报的预置“自定义”屏幕无需配置,使设置变得简单。有 2 种尺寸可供选择(10 英寸和 15 英寸),您可以在一台显示器上查看多达四个独立 3500 机架的数据。显示模块也有安装选项,包括铰链式和锁定式面部安装。危险区域认证可用于显示器。

3500机械保护系统速度监视器

TACH100 数字转速计 可以用作独立的速度指示器,也可以与任何 安装的监控系统一起用作远程速度指示器。紧凑型装置包含自己的电源,当需要在机器附近或远处安装 监控系统以指示速度时,这很方便。数字转速计提供本地显示,指示机器甲板上的机器速度。当需要双耳保护时,数字转速计会提供视觉指示。电线可以与显示器机架上的键相量接近探头输入并联,或直接连接到键相量接近探头。TACH100 接受来自外部供电的键相接近探头的信号线和公共线。

我们的 3500/25 键相模块 在 3500 机架中提供相位参考信息(每个 3500 机架 多可以使用四个键相器),从而实现高级机械诊断。它接收来自接近探头或磁性拾音器的输入信号,并将每转一次或每转多次事件的脉冲信号转换为 的数字定时测量。这允许您的 3500 系统测量机器速度和矢量参数,例如 1X 振动幅度和相位,这些是确定重要机器行为的关键。键相量测量也是 Bently Nevada† 汽轮机监控仪表 (TSI) 传感器套件的一个组成部分, 用于汽轮机。3500 系统可作为 SIL 2 级系统使用,并通过了多项危险区域和/地区特定认证,可应对任何环境。

我们的 3500/50M 转速计模块 具有 2 个通道,接受来自前置器探头或磁性拾音器的输入,以测量轴转速、转子加速度或反向旋转。3500/50M 转速计调节输入并将调节后的信号与用户可编程的设 进行比较,这些设 可以驱动 3500 继电器模块中的警报和继电器逻辑。3500 机架配置软件提供的报警选项包括速度带、零速、转子加速度和反向旋转。键相量和速度测量也是本特利内华达汽轮机监控仪表 (TSI) 汽轮机传感器套件的组成部分。3500 系统可作为 SIL 2 额定系统使用,并具有多个危险区域和特定/地区的批准。还提供外部终端和内部屏障版本。 不适 用于超速检测。

Product characteristics

The 3500 Series Protection and Condition Monitoring System is a flexible, scalable platform for continuous online monitoring of critical machines as well as all other machine assets used in plant-wide processes, all in one integrated system.

Reliable compliance

Compatible and flexible

Communicate with system 1

Available options

Safety certification

3500 Mechanical protection system display

The 3500/94M VGA touch screen display module with color touch screen and I/O module displays important 3500 data in the machine or control room. VGA features 3,500 vibration levels, a list of system and alarm events, as well as module, channel and alarm data, and nine custom display options. Preset "custom" screens for Direct, 1X, Gap, and alerts require no configuration, making setup simple. Available in 2 sizes (10-inch and 15-inch), you can view data from up to four separate 3,500 racks on a single display. The display module also has mounting options, including hinged and locked face mounts. Hazardous area certification is available for displays.

3500 Mechanical Protection system speed monitor

The TACH100 digital tachometer can be used as a standalone speed indicator or as a remote speed indicator in conjunction with any installed monitoring system. The compact unit contains its own power supply, which is handy when a monitoring system needs to be installed near or far from the machine to indicate speed. The digital tachometer provides a local display indicating the machine speed on the machine deck. A digital tachometer provides visual indication when protection of both ears is required. The wire can be connected in parallel to the key phasor proximity probe input on the display rack or directly to the key phasor proximity probe. The TACH100 accepts signal lines and common lines from externally powered keys close to the probe.

Our 3500/25 key phase module provides phase reference information in 3500 racks (up to four key phasers per 3500 rack) for advanced mechanical diagnostics. It receives an input signal from a close probe or magnetic pickup and converts the pulse signal of one or multiple events per revolution into a digital timing measurement. This allows your 3500 system to measure machine speed and vector parameters, such as 1X vibration amplitude and phase, which are key to determining important machine behavior. Key phasor measurement is also an integral part of the Bently Nevada† Turbine Monitoring Instrument (TSI) sensor suite for steam turbines. The 3500 system can be used as an SIL Level 2 system and has multiple hazardous area and/or area specific certifications to handle any environment.

Our 3500/50M tachometer module has 2 channels and accepts input from the preprocessor probe or magnetic pickup to measure shaft speed, rotor acceleration or reverse rotation. The 3500/50m tachometer adjusts the input and compares the adjusted signal with user-programmable Settings that drive the alarm and relay logic in the 3500 relay module. Alarm options provided by the 3500 rack configuration software include speed bands, zero speed, rotor acceleration, and reverse rotation. Bond phasor and velocity measurements are also part of the Bentley Nevada Turbine Monitoring Instrument (TSI) turbine sensor suite. The 3500 system can be used as an SIL 2 rated system with multiple hazard zones and specific/regional approvals. External terminal and internal barrier versions are also available. Not applicable to speed detection.

相关推荐