手机:17359299796

手机:17359299796— 产品中心 —

全国免费客服电话 17359299796

全国免费客服电话 17359299796 邮箱:A3669372910@163.com

手机:17359299796

电话:17359299796

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

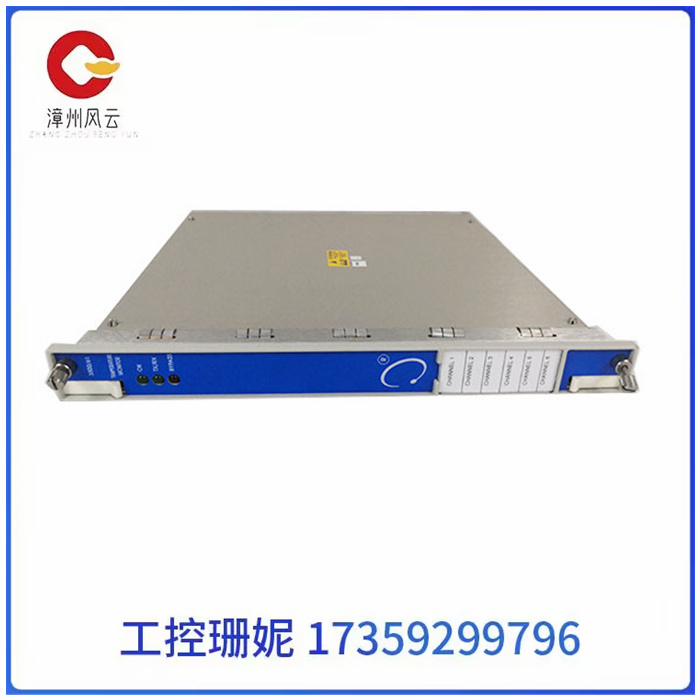

本特利 bently 3500/61 温度监测器品牌BENTLY规格本特利 bently 3500/60 和 3500/61 温度监测器颜色以实物为准特点全新加工定制否物料编码bently 3500/60 和 3500/61 温度监测器输出频率标准kHz系统环境稳定系统能力正常操作系统DCS/PLC系统系统功能正常可售卖地全国用途PLC/DCS系统本特利 bently 3500/61 温度监测器P

产品详情

本特利 bently 3500/61 温度监测器

本特利 bently 3500/61 温度监测器

PLC发展到今天,已经形成了各种规模的系列化产品,可以用于各种规模的工业控制场合。除了逻辑处理功能以外,PLC大多具有完善的数据

bently 3500/61 温度监测器运算能力,可用于各种数字控制领域。多种多样的功能单元大量涌现,使PLC渗透到了位置控制、温度控制、CNC等各种工业控制中。加上PLC通信能力的增强及人机界面技术的发展,使用PLC组成各种控制系统变得非常容易。

PLC是面向工矿企业的工控设备。它接口容易,编程语言易于为工程技术人员接受。

DCS系统的特点:

高可靠性,因它基于多台计算机控制,且系统架构采用了硬件冗余,网络容错设计,即使某个硬件出现故障,系统也能在ms级恢复,不会影响系统的正常运行。

开放性,因它采用开放式,标准化,模块化,网络化设计,当需要增加或者改变一些功能时,可以通过增改硬件配置的方式实现要求。

灵活性,当控制要求变更时,可以通过编程软件实现各种逻辑控制,复杂的算法,图形化显示等功能要求。

本特利 bently 3500/61 温度监测器

PLC development to today, has formed a variety of scale of serialized products, can be used in various scales of industrial control occasions. In addition to logical processing functions, most PLCS have perfect data

The computing power of the bently 3500/61 temperature monitor can be used in various fields of digital control. A large number of various functional units have emerged, so that PLC has penetrated into various industrial controls such as position control, temperature control, CNC. With the enhancement of PLC communication capability and the development of human-machine interface technology, it is very easy to use PLC to form various control systems.

PLC is an industrial control equipment for industrial and mining enterprises. Its interface is easy and the programming language is easy to be accepted by engineers and technicians.

DCS system features:

High reliability, because it is based on the control of multiple computers, and the system architecture adopts hardware redundancy, network fault-tolerant design, even if a hardware failure, the system can be recovered at the ms level, will not affect the normal operation of the system.

Openness, because it uses an open, standardized, modular, networked design, when you need to add or change some functions, you can achieve the requirements by changing the hardware configuration.

Flexibility, when the control requirements change, you can realize a variety of logic control, complex algorithms, graphical display and other functional requirements through programming software.

相关推荐