手机:17350880093

手机:17350880093— 产品中心 —

全国免费客服电话 17350880093

全国免费客服电话 17350880093 邮箱:sales@flplc.cn

手机:17350880093

电话:17350880093

地址:福建省漳州市龙文区朝阳北路1号办公楼205室

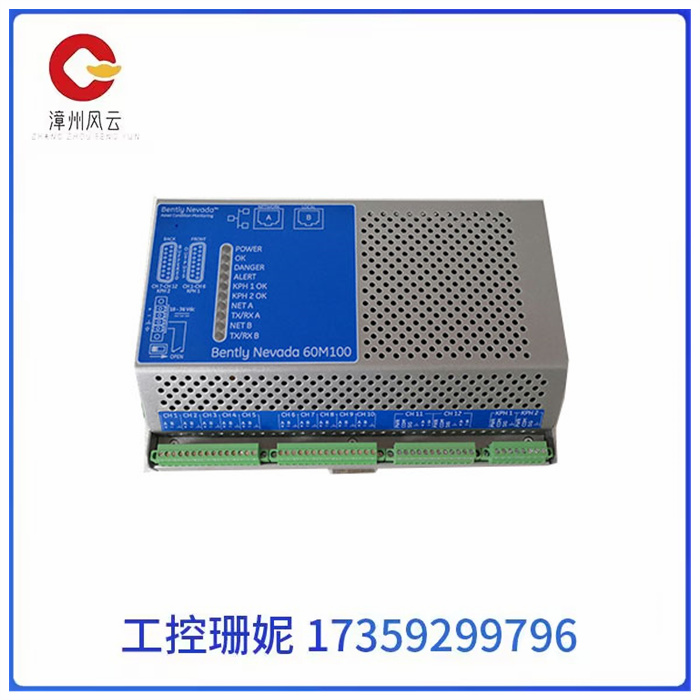

BENTLY NEVADA 60M100-00 本特利模块 全新库存品牌BENTLY加工定制否工作电压220V特点编程简单方便外壳颜色白色质量认证CCC输出频率CCC效率效率高产地美国质保一年可售卖地全国用途系统控制型号60M100-00BENTLY NEVADA 60M100-00 本特利模块 全新库存以下是Bently 60M100-00电源模块在振动监测和测量设备中的主要应用领域:旋转机械监

产品详情

BENTLY NEVADA 60M100-00 本特利模块 全新库存

BENTLY NEVADA 60M100-00 本特利模块 全新库存

以下是Bently 60M100-00电源模块在振动监测和测量设备中的主要应用领域:

旋转机械监测:在工业设备中,如发电机、泵、风机、齿轮箱等旋转机械,振动监测是一种常用的技术,用于检测旋转机械的运行状态和健康状况。

轴承监测:轴承是工业设备中常见的易损件,通过振动监测可以实时检测轴承的状态,及时发现异常,避免轴承故障引发更大的损失。

叶片监测:在风力发电和涡轮机等设备中,叶片的状态直接影响设备性能,振动监测可用于叶片的健康状况评估。

故障诊断:Bently 60M100-00电源模块可以用于振动监测设备中的故障诊断,通过收集和分析振动数据,实现对设备故障原因的定位和分析。

预防性维护:通过振动监测,可以实现设备的预防性维护,及时发现和解决潜在问题,延长设备的使用寿命,降低维修成本。

BENTLY NEVADA 60M100-00 本特利模块 全新库存

The following are the main application areas of the Bently 60M100-00 power module in vibration monitoring and measurement equipment:

Rotating machinery monitoring: In industrial equipment, such as generators, pumps, fans, gear boxes and other rotating machinery, vibration monitoring is a commonly used technology to detect the operating status and health of rotating machinery.

Bearing monitoring: bearing is a common wearing part in industrial equipment, vibration monitoring can detect the status of bearings in real time, timely detection of anomalies, to avoid bearing failure caused by greater losses.

Blade monitoring: In equipment such as wind power generation and turbines, the state of the blade directly affects the performance of the equipment, and vibration monitoring can be used to assess the health of the blade.

Fault diagnosis: The Bently 60M100-00 power module can be used for fault diagnosis in vibration monitoring equipment. By collecting and analyzing vibration data, the cause of equipment failure can be located and analyzed.

Preventive maintenance: Through vibration monitoring, preventive maintenance of equipment can be realized, potential problems can be discovered and solved in time, the service life of equipment can be extended, and maintenance costs can be reduced.

相关推荐